- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

150 Ton Motorised Hydraulic Production Press

Product Code: PPHD150Our 150-ton hydraulic production press is ideal for stamping, die-cutting, deep drawing, and forming applications. It is designed to seamlessly integrate into automated production lines, offering enhanced efficiency and versatility.

The press is equipped with mechanized upper and lower tables, both featuring T-grooves for secure part holding. Cylindrical lateral guides ensure precise alignment of the upper table, enhancing consistency. The NC-control system allows for digital adjustment of pressure, piston stroke, and holding time, while also enabling the storage of up to 100 different working cycles. The press is operated using a foot pedal for smooth and efficient control.

Manufactured in Europe and built to meet the latest CE standards, this robust production press guarantees high quality and long-lasting performance.

Please contact for prices

- Description

- Additional Info

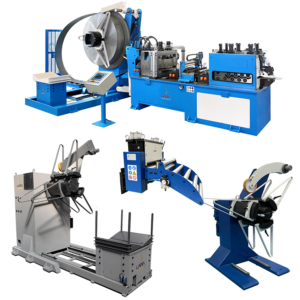

The 150 Ton Motorised Hydraulic Production Press is designed for demanding industrial applications such as deep drawing, stamping, and punching. Built with a rugged electro-welded frame using S355JR steel, this press offers high durability and precision. Operating at a maximum pressure of 320 BAR, it delivers reliable performance and longevity. The press can be seamlessly integrated into production systems or coil feeding and straightening systems, available from Workshop Press Co UK, optimizing productivity and efficiency for manufacturing processes.

Technical Specifications:

- Pressure Force: 150 tons

- Motor Power: 7.5 kW

- Working Speed: 4.3 mm/sec

- Approaching Speed: 20 mm/sec

- Returning Speed: 26.7 mm/sec

- Piston Stroke: 400 mm

- Vertical Light: 480 mm

- Frontal Light: 920 mm

- Lower Table Size: 850 x 600 mm

- Upper Table Size: 720 x 460 mm

- Guide Diameter: 80 mm

- Table / Working Height: 875 mm

- Total Length (Lateral): 1200 mm

- Total Width (Frontal): 1730 mm

- Overall Height: 2850 mm

- Weight: 3650 kg

Features & Uses:

- Sturdy Machine Frame: Designed for robust performance

- Upper and Lower Tables: Equipped with T-grooves for secure workpiece holding

- Cylindrical Lateral Guides: Ensure accurate alignment of the upper table

- Adjustable Piston Stroke: For versatile processing

- Operation Mode Selector: Choose between manual, semi-automatic, or automatic modes

- Dual-Speed Selector: Adjust for single or double-speed operations

- Pressure Switch and Manometer: For easy monitoring and control of pressure

Optoinal Accessories:

- Increased approach and return speeds with pre-filling valves and lateral cylinders

- Hydraulic Cushion: For additional material support

- Hydraulic Ejector: Available for the upper or lower table, or both

- Cooling System: Air-oil cooling for the hydraulic group

150 Ton Motorised Hydraulic Production Press ideal for deep drawing, stamping, and punching tasks. Easily integrates into production systems or coil feeding and straightening systems offered by The Workshop Press Co UK.