We Are The Press People

At Workshop Press, our hydraulic presses power industries worldwide. From metal fabrication to advanced manufacturing, our precision machines are engineered to deliver results. Discover our extensive range of presses tailored to meet your unique needs.

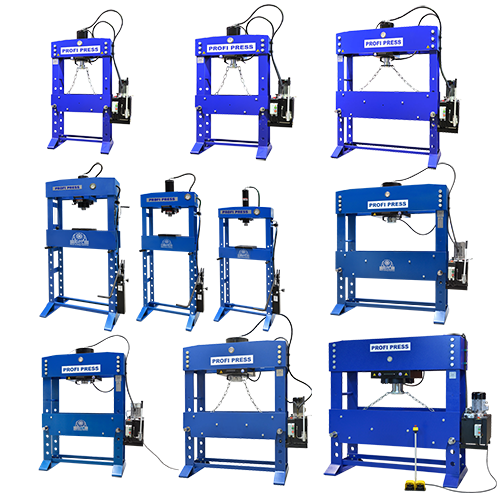

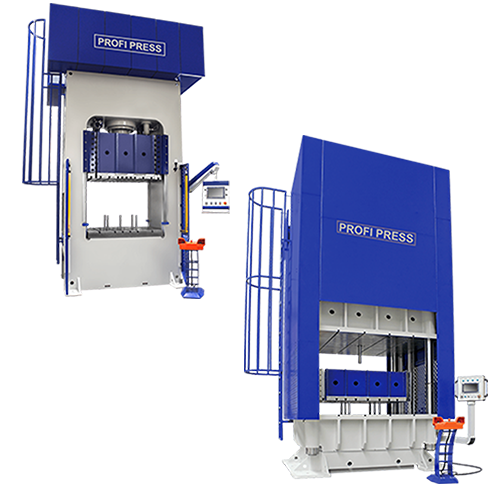

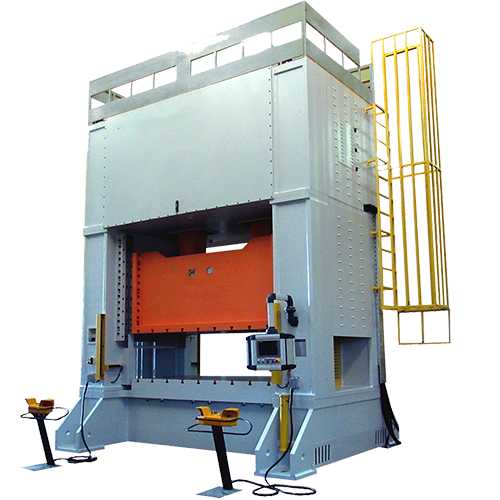

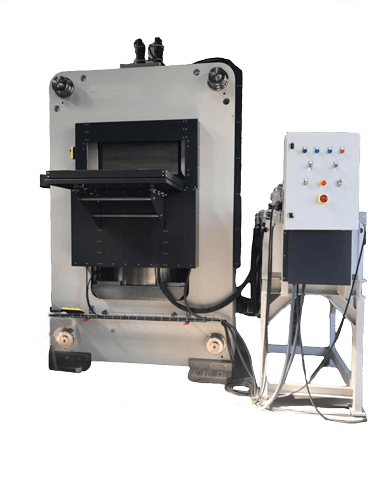

Common Hydraulic Press Types

to be classified as a Hydraulic Press, the pressing machine must employ at least one hydraulic cylinder. The name or definition of the press relies on the framework or structure of the press. The following list describes the most common hydraulic presses on the market:

The press categories displayed include a wide variety of tonnages and frameworks. All presses are customizable with common modifications such as changes to physical dimensions, bolster and slide table sizes, enhanced controls, and integrated safety systems.

Common Hydraulic Press Uses and Applications

What are hydraulic presses used for? Hydraulic presses are very useful for industrial purposes. They have many applications and many industrial environments have uses for them. For instance, some hydraulic press uses include:

|

|

Hydraulic presses all differ in tonnage, the application will determine the tonnage you will need to use.

How Does A Hydraulic Press Work?

The hydraulic press operates by filling the cylinder with hydraulic fluid which then applies pressure to the piston. As the pressure increases, the hydraulic fluid transmits this force to the piston situated in the larger cylinder. The intensified pressure is then exerted onto the material being worked on, such as metal or other materials.

This powerful force enables the hydraulic press to form or shape the material according to the desired outcome. For instance, it can crush or bend metal sheets, or compress materials into specific forms.

Once the desired shape or transformation is achieved, the pressure on the piston is released, and the hydraulic press returns the piston to the set home position to allow the metal press to repeat the process for subsequent tasks. The cyclic nature of applying and releasing pressure makes the hydraulic press versatile and capable of producing a wide range of products.

Related: How Hydraulic Presses Help With the Production Process

Benefits Of A Hydraulic Press

- Consistent tonnage – A hydraulic press can generate full pressing force anywhere in the stroke. This gives you more control over travel distance, pressure, and return position.

- Customisation – Hydraulic presses can be used for even the most complex parts. We can modify a current design, or develop a custom press to meet your specific requirements.

- Small footprint – Hydraulic presses can generate high pressure over a small surface area. So, they take up a lot less footage than many other industry machines.

- Economical – Due to the simplicity of the hydraulic press design they very rarely breakdown, this means less outlay on maintenance. However, should it fail, parts are easy to come by and easy to replace.

- Longer Tool Life – A hydraulic press tool is designed to fit the application, not the press. Also, overload protection minimises the damage on tooling, thereby extending the tool life.

Related: Benefits Of Utilising A Custom Hydraulic Press For Production

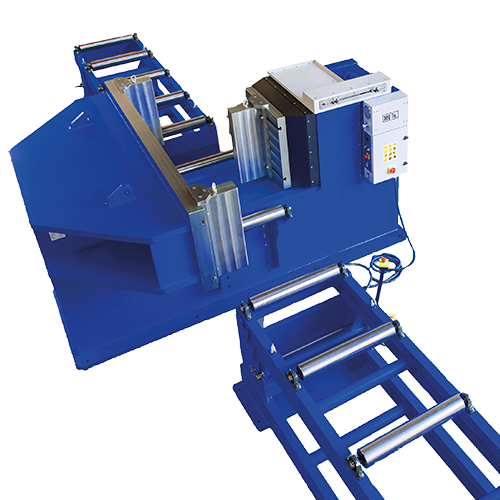

Coil Feeding Systems

Coil feeders are an essential piece of equipment for any metal stamping operation. They are used to automatically feed metal coils into presses, which can help to improve productivity and reduce labor costs.

Coil feeders are typically used in conjunction with presses to automate the metal stamping process. The coil feeder will uncoil the metal from the coil and feed it into the press at a constant speed. The press will then stamp the metal into the desired shape. Metal Stamping Presss Coil Feeders can be used with a wide variety metal materials, including steel, aluminum, and copper. They are available in a variety of sizes to accommodate different coil widths and thicknesses.

In addition to improving productivity and reducing labor costs, coil feeders can also help to improve product quality. By automating the metal stamping process, coil feeders can help to ensure that the metal is fed into the press consistently and accurately. This can help to reduce the number of defects in the finished product.

If you are looking for a way to improve the efficiency and productivity of your metal stamping operation, then a coil feeder is a great option. Coil feeders can help you to save time and money, while also improving product quality.

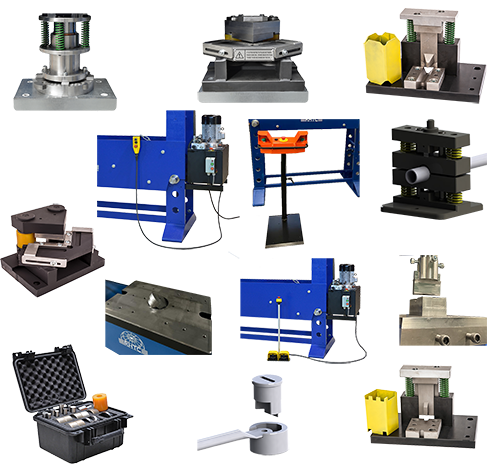

Press Accessories and Tools

Hydraulic Press Accessories are designed to optimize your metalworking operations and they a variety of custom and bespoke tools that can be tailored to suit your specific manufacturing needs. From single-stage to progressive tools, each accessory enhances both basic and complex manufacturing environments, ensuring efficiency and precision. Safety is paramount with options like hydraulic press guarding systems and dual palm button controls, providing enhanced operator safety. Hydraulic Power Press accessories also feature advanced components such as PLCs, HMIs, and digital pressure gauges, integrating seamlessly with Hydraulic Workshop Presses to streamline production processes. Explore our comprehensive range of accessories today to elevate your metalworking capabilities. For more details and to view our full selection, click HERE.

- Custom and Bespoke Tools

- Single-stage and progressive tools for one-off and continuous production runs

- Corner notchers, pipe notchers, and sheet bending tools

- Tool Holders and Adapters

- End cap tool adapters

- Slotted tool holders

- Work Tables

- Motorized work tables with tool holders and press brake attachments

- Work tables with locating and mounting holes, center holes for tools, and slug dropouts for various tonnage presses

- Die Sets

- Empty die sets for various presses, accepting a wide range of pressing tools

- Punching Tools

- Mandrel sets for punching and pressing pins

- Punch and die kits with various punches and dies

- Wedge-shaped punching devices for flat sheets, bars, and tubes

- Control Systems

- Handheld pushbutton piston control

- Foot pedal stroke control

- Dual palm button safety control

- Safety Devices

- Hydraulic press guarding with light curtains and mesh side curtains

- Perspex enclosure guarding

- Safety cage guarding with swing doors or upward-moving fronts

- Digital and Pressure Gauges

- Digital pressure gauges (manometers)

- Specialized Tooling

- Tube forming and punching tools for metal fabrication

- V-block sets for various tonnage presses

- Corner rounding tools with multiple radii

- Pipe notchers for various pipe diameters

- Rod cutters for workshop presses

Installations, Placement, Connections, & Training

ensure seamless integration of your hydraulic press with a comprehensive installation service. Make sure to use expert teams to manage everything from site preparation to final connection, ensuring your press is operational and optimized for performance. Additionally, services such as training programs to familiarize your staff with safe operation and maintenance practices, and maximize productivity and longevity of your equipment.

International Crating and Shipping

At Workshop Press, we offer global shipping for all our machines, ensuring safe and secure transport to your desired location. Our team arranges specialized crating solutions to protect your machinery throughout its journey. Whether it’s road, sea, or air freight, we coordinate shipping services from door to door, or any other specific arrangements you require.

With our comprehensive logistics support, you can trust that your machine will arrive in perfect condition, no matter where in the world you are. We provide ISPM 15 certified crating and expert shipping solutions to meet your needs.

The Workshop Press Company UK | Contact Us Today

Head to our website for more information, or call 0800 999 1090 to speak to a member of our helpful and friendly team at Workshop Press. Furthermore, if you have found this blog helpful, you may wish to read our previous blog on Manual Hydraulic Press Basics.