- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

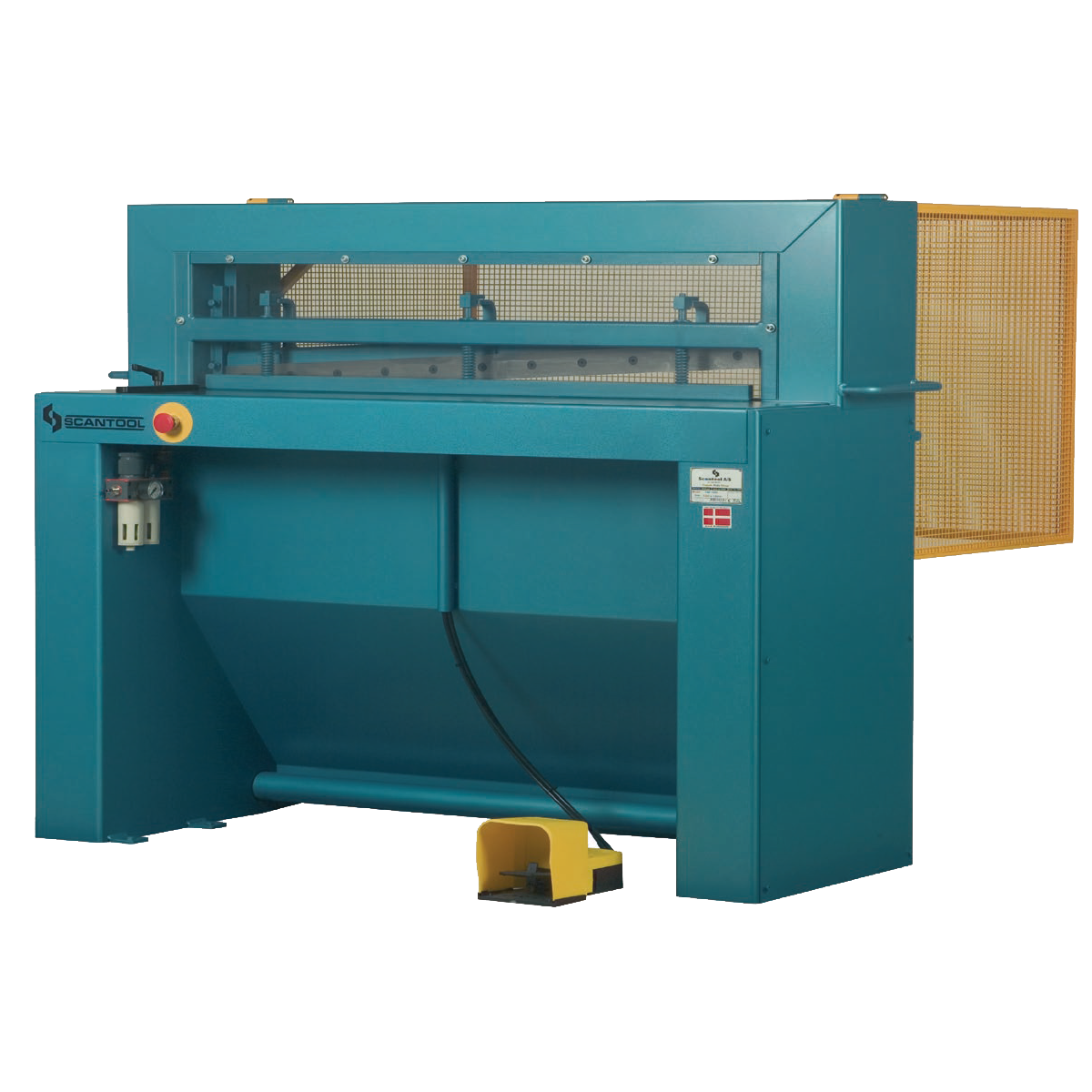

Guillotine Shear for Metal • Pneumatic • Scantool

Product Code: 530601800The Scantool power shears are manufactured with an appropriate working height, self-lubricating guides, spherical ball bearings, and a large range of optional accessories is offered.

Scantool metal fabricating machines are manufactured in the EU with only the best materials and components.

Please contact for prices

- Description

- Additional Info

- 2mm Mild Steel

- 1.55mm Stainless

- 1330mm Cutting Length

- Manual Backgauge

- Strokes/Minute: 26

Technical specifications for Scantool Pneumatic Guillotine Shear Model TSP-1300/2

- Manual back gauge ✓

- Capacity (mm) 1330 x 2.0

- Cutting angle 3°

- Cutting/min. 15

- Machine height (mm) 1300

- Machine length (mm) 1680

- Machine width (mm) 1210

- Net weight (kg) 310

- Normal liter (air) per cycle 43

- Pladeanslag (mm) 550

- Side stop (mm) 200

- Tank capacity (L) 80

- Working width (mm) 1330

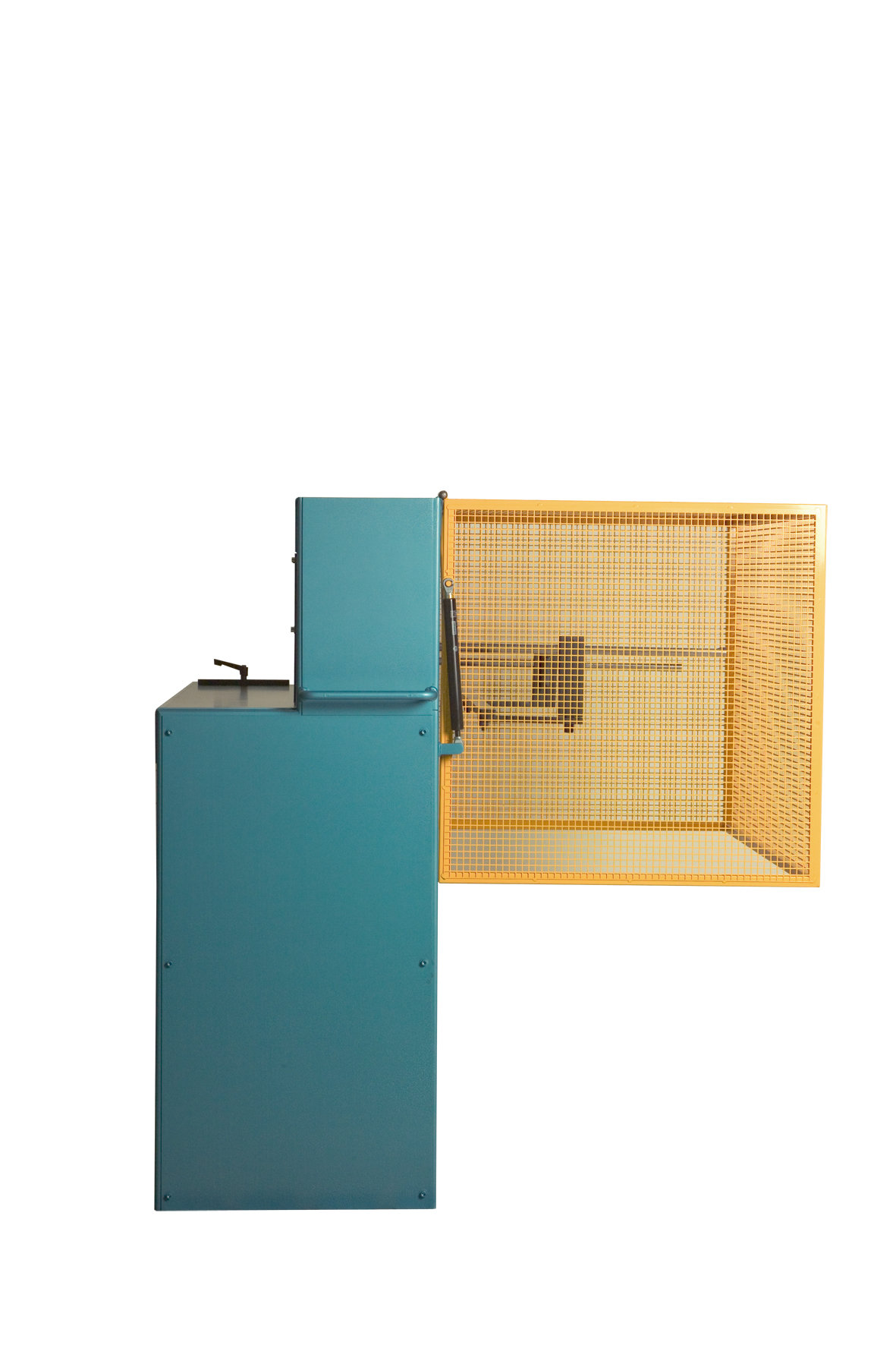

Features

- Danish top quality and finish to the smallest details

- Solid, compact welded steel construction

- Operated pneumatically by a pedal

- Cuts metal, plastic foil and other materials

- Automatic sheet holder coated with neoprene rubber

- Offers good visibility of the complete cutting length

- The knives are made of strong tool steel, and are reversible which doubles the cutting surface

- Has a sliding joint and the knife can be adjusted easily using the 6 Allen screws and counter nuts

- Built in working light

- Safety system according to CE Regulations

- Emergency stop.

- Working table with adjustable angle stop and safety stop.

- Manual back gauge with millimetre gauge up to 550 mm.

Guillotine Shears

Guillotine Shears can be manually, electrically, or pneumatically powered and are designed to cut large pieces of sheet metal into smaller strips and shapes and cut in straight line. The capacity of metal guillotines shears vary greatly and their overall size and weight typically correlate with their top-end cutting capacity.