Custom Controlled Press Line

Product Code: Custom Workshop PressAny RHTC Profi Press can be Customised

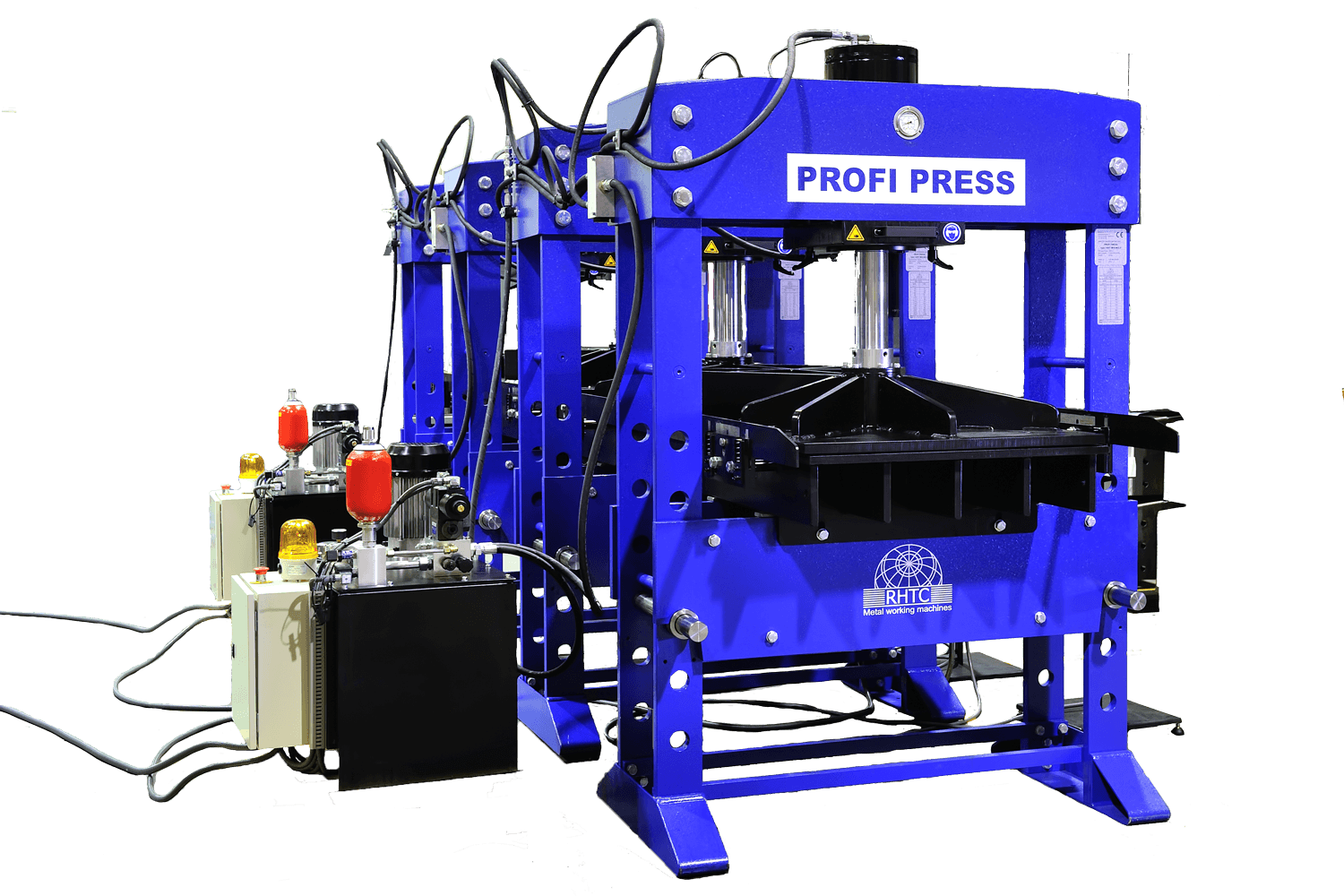

The Workshop Press Company UK or WorkshopPress.CO.uk offers and stocks RHTC custom-made presses and all of our sales and service are based in Warwickshire. Displayed here is a series of 4 of our standard 100-ton Hydraulic Workshop Presses designed especially to carry out the forming of plastic material.

The bespoke press line has supply rails, a heating element section, a cooling section, and the whole system is PLC-controlled to regulating the pressure, cycle-times, and the stroke and pressure of the pistons. The production process involved placing the material in the heating section of the first two presses. In this section of the press series, the material is heated and formed with constant pressure during 40 minutes cycle. After the 40 minutes cycle is complete, the material is slid into the cooling region of the second two presses and the same process and production cycle takes place but with a low temperature.

WokshopPress.co.uk offers the broad range of RHTC hydraulic presses all of which can be modified or customised to suit your needs. As you see here the presses can also be integrated into production systems that help our customers save time and make more money.

In addition to modifying and integrating the standard presses, we can produce presses that are truly a one-off or that are completely bespoke. There are no limitations on what we can offer as far as pressing applications are concerned, so contact WorkshopPress.co.uk today to discuss your press needs.

Call us on 0800 999 1090 or Email us at info@WorkshopPress.CO.uk today to discuss your application or to receive more information on RHTC Presses.

Please contact for prices

- Description

- Additional Info

Technical specifications for Custom Controlled Press Line

• Max. pressure force [kN]: 685

• Maximum pressure [bar]: 180

• Piston stroke [mm]: 380

• Approaching speed [mm/sec]: 10

Features

• Supply Rails

• Heating Zone on Platen

• Cooling Zone on Platen

• PLC control to regulate the pressure, cycle time, and position of the piston

WorkshopPress.co.uk offers and stocks RHTC custom-made presses and all of our sales and service are based in Warwickshire. Displayed here is a series of 4 of our standard 100-ton Hydraulic Workshop Presses designed especially to carry out the forming of plastic material.

The bespoke press line has supply rails, a heating element section, a cooling section, and the whole system is PLC-controlled to regulating the pressure, cycle-times and the stroke and pressure of the pistons. The production process involved placing the material in the heating section of the first two presses. In this section of the press series the material is heated and formed with constant pressure during 40 minutes cycle. After the 40 minutes cycle is complete, the material is slid into the cooling region of the second two presses and the same process and production cycle takes place but with a low temperature.

WokshopPress.co.uk offers the broad range of RHTC hydraulic presses all of which can be modified or customised to suit your needs. As you see here the presses can also be integrated into production systems that help our customers save time and make more money.

In addition to modifying and integrating the standard presses, we can produce presses that are truly a one off or that are completely bespoke. There are no limitations on what we can offer as far as pressing applications are concerned, so contact WorkshopPress.co.uk today to discuss your press needs.

[maxbutton id="1" url="mailto:info@workshoppress.co.uk?subject=Please Contact me regarding a bespoke press application&body=Please provide your Name, Company Name, and Phone Number along with any and all other pertinent details."]