Portal Roll Frame Press • 100 Tons • RHTC

Product Code: PPTL20058The PPTL-100 Roll Frame Portal Press is engineered for efficient metalworking applications that require both high force and precision. With a pressure force of 981 kN, this portal press is ideal for tasks like straightening, bending, and assembling heavy components. The manually movable portal and movable cylinder (left-right) enhance flexibility, making it easy to align the press for precise operations. The design of the portal press allows for heavy material to be placed on the table using a crane, and the portal can then be slid over the material when pressing starts, simplifying the handling of large workpieces.

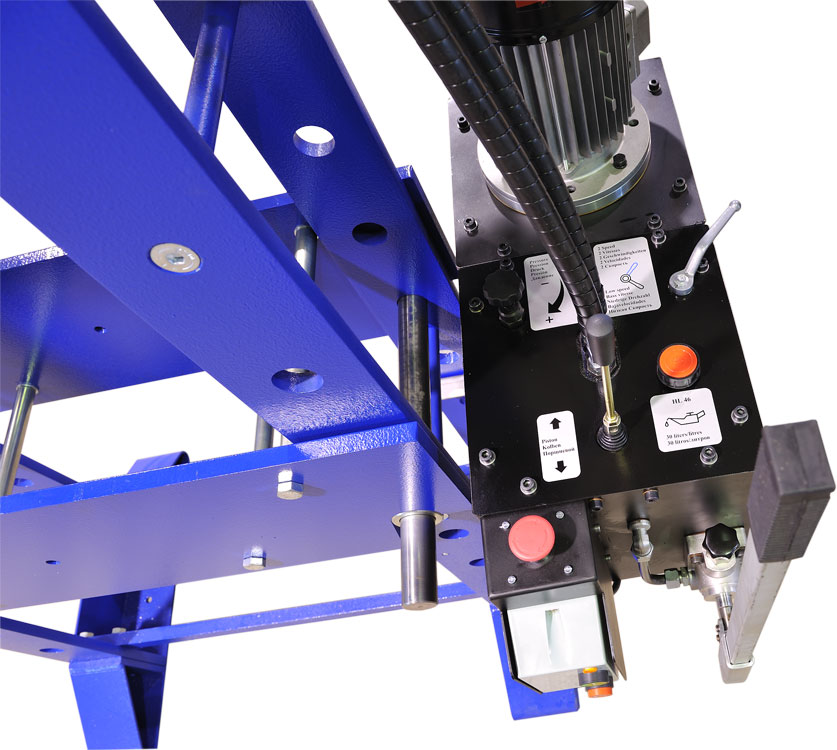

The press is equipped with an integrated pressure manometer, pressure regulation, and a hydraulic unit with two-speed options to accommodate various processing needs. It also features a joystick/directional control valve for cylinder movement and a hand pump for precise press work, allowing fine control during critical operations.

Standard or customized to fit your requirements, the PPTL-100 is designed to provide both power and control, ensuring that even the most challenging projects are completed with ease. Our 100-ton portal press is directly available from our stock in the Netherlands, and we can easily customize these hydraulic presses, whether you need a larger table, a longer piston stroke, or more clearance between the piston and the table.

Please contact for prices

- Description

- Additional Info

The PPTL-100 Roll Frame Portal Press is a robust and versatile hydraulic press designed for heavy-duty applications with a pressing force of 981 kN. Featuring a manually movable portal and a movable cylinder, it allows flexible positioning, making it ideal for operations requiring precision and adaptability. Exclusively made in Europe, this portal press is suitable for a wide range of metalworking and fabrication tasks, providing excellent performance and reliability in demanding environments. Thanks to the movable portal and cylinder, users can easily reach every point of the surface to be pressed, which facilitates precise and efficient work.

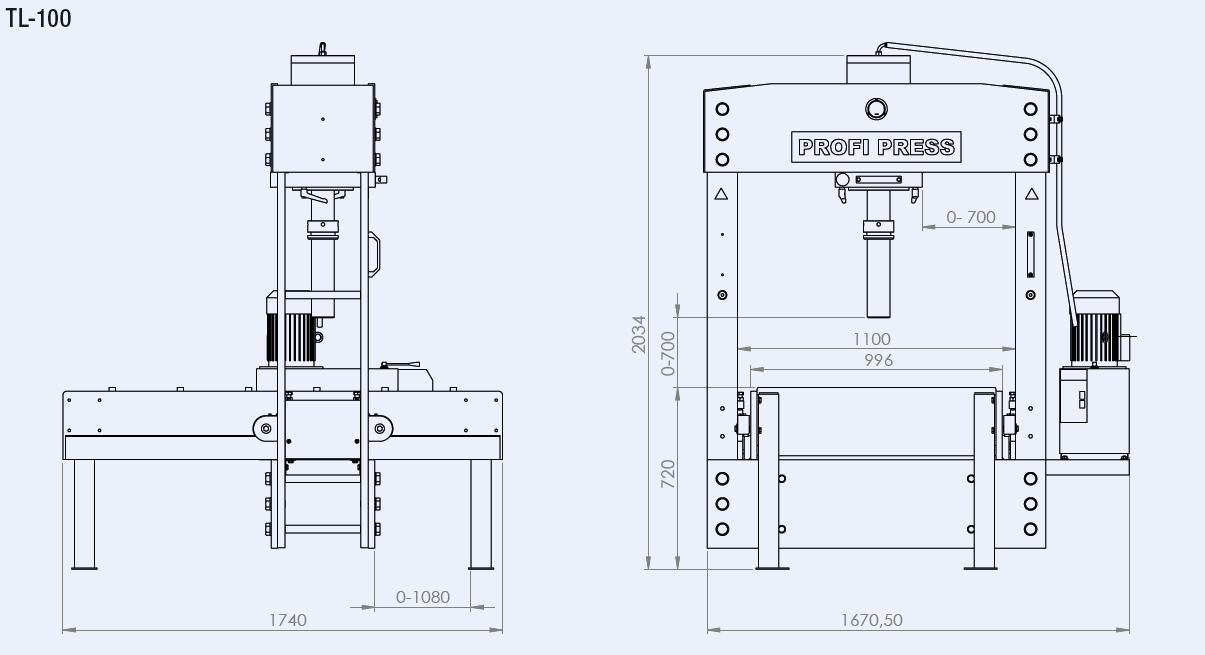

Technical Specifications

- Pressure force [kN]: 981

- Pressure max. [bar]: 258

- Cylinder stroke (with cylinder extension) [mm]: 380

- Press speed [mm/sec]: 47

- Cylinder lowering speed [mm/sec]: 54

- Return speed [mm/sec]: 9.06

- Motor [kW]: 2

- Voltage [V]: 400V, 50 Hz, 3-Phase

- Speeds (incl. pressure regulation): 2

- Table size (L x W) [mm]: 1740 x 996

- Working width [mm]: 1100

- Vertical light [mm]: 700

- Working height [mm]: 720

- Total height [mm]: 2034

- Total length [mm]: 1740

- Total width [mm]: 1670

- Weight [kg]: 1650

Features

- Manually movable portal for flexible positioning

- Movable cylinder (left-right) to reach various workpoints

- Cylinder extension to reach the table

- Integrated pressure manometer for monitoring

- Pressure regulation for precision control

- Hydraulic unit with two-speed operation for versatile use

- Joystick/directional control valve for cylinder movement

- Hand pump for detailed and precise press work

- Made exclusively in Europe

- 2-year warranty

- Built in the EU

- CE Certified

- Suitable for straightening, bending, and assembly tasks

- Heavy material handling facilitated by crane access and movable portal

Optional Accessories

- 1 Phase Motor (50 or 60 Hz)

- 60 Hz motor (1 or 3 Phase)

- 1 Phase Motor

- Geometry adapted to your requirements

- V-Blocks

- Press Brake Attachments

- Adjustable Pressing Plates

- Die Sets

- Hydraulic Foot Pedal Control

- Extended Cylinders

- Piston Attachments

- Digital Pressure Gauge

- Custom Table Plates

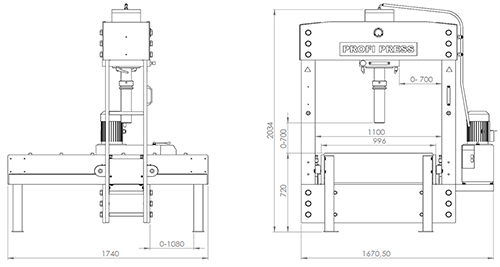

PPTL-100 Standard Dimensions

100-ton hydraulic Roll Frame Portal Press with manually movable portal and a working width of 1100 mm. Made in Europe. Ideal for precision metalworking, featuring a movable cylinder and integrated pressure regulation.