220 Ton Motorised Portal Press – PPTLM Series • RHTC

Product Code: PPTLM220The 220 Ton Motorised Portal Press - PPTLM-220 is designed for straightening large and heavy structures or sheets with precision and ease. Featuring a motorised movable frame and cylinder, this press ensures seamless access to various pressing and straightening points. The longitudinal displacement of the frame is driven by a frequency inverter and cogged belt for precise sliding, while the lateral movement of the cylinder is motorised for enhanced control.

Equipped with a spacious lower table (2,000 x 3,500 mm), this portal press simplifies the handling of large workpieces. Operation is conducted via a wireless remote control with an integrated emergency stop, ensuring both convenience and safety. Built to CE standards and backed by a two-year warranty, the PPTLM-220 is a reliable choice for heavy-duty straightening tasks.

Contact us today to learn more or request a customized hydraulic portal press to meet your specific requirements.

Please contact for prices

- Description

- Additional Info

The 220 Ton Motorised Portal Press – PPTLM-220 offers unparalleled versatility and precision for industrial applications.

Key Benefits:

- Movable Frame and Cylinder: Access multiple pressing and straightening points with ease.

- Advanced Precision: Longitudinal displacement powered by a frequency inverter and cogged belt ensures accurate sliding.

- Spacious Table: Large lower table (2,000 x 3,500 mm) accommodates extensive workpieces.

- Wireless Control: Operate the press remotely with integrated safety features like emergency stop.

- CE Compliance: Meets essential health and safety requirements with a two-year warranty included.

Customizable options, including larger tables or additional features, are available upon request.

Technical Specifications

- Force: 220 tons

- Motor Power: 5.5 kW

- Working Speed: 3 mm/sec

- Approaching Speed: 9 mm/sec

- Return Speed: 16.2 mm/sec

- Maximum Pressure: 250 bar

- Piston Stroke: 460 mm

- Table Size: 3500 x 2000 mm

- Horizontal Light: 2050 mm

- Vertical Light: 850 mm

- Headstock Displacement: 1350 mm

- Frame Displacement: 2650 mm

- Working Height: 800 mm

- Total Length: 4000 mm

- Total Width: 3200 mm

- Overall Height: 3100 mm

- Weight: 12000 kg

Key Features

- Motorised movable portal

- Motorised movable cylinder

- Cylinder stroke is easy to regulate with the end-stroke switches

- Selector for manual or semi-automatic operation

- Pressure regulator and manometer

- Wireless remote control

Optional Accessories

- Milling flat table (3500 x 2000 x 85 mm)

- Small cylinders fitted in the lower table to lift pieces (each 2 ton power), connected to a second hydraulic group

- Additional extension for the cylinder

- Larger table size

Industries Using the Machine

- Railway Industry: Maintenance, fabrication, production, testing

- Shipbuilding Industry: Structural fabrication, repair, component testing

- Aerospace Industry: Component forming, maintenance, stress testing

- Manufacturing: General fabrication, assembly, material testing

Benefits of Motorised Portal Presses

- Motorised roll frame hydraulic presses for heavy-duty applications

- Easy-to-position motorized gantry for precise alignment

- High-capacity presses: 160 Ton, 220 Ton, 300 Ton models available

- Double-acting cylinders for fast retraction and efficiency

- Integrated pressure gauges for enhanced safety and control

- Two-speed hydraulic pump for flexible operation

- Ideal for railway, s

Benefits of Motorised Portal Presses (cont.)

- Low maintenance design with minimal downtime

- Versatile press suitable for vari

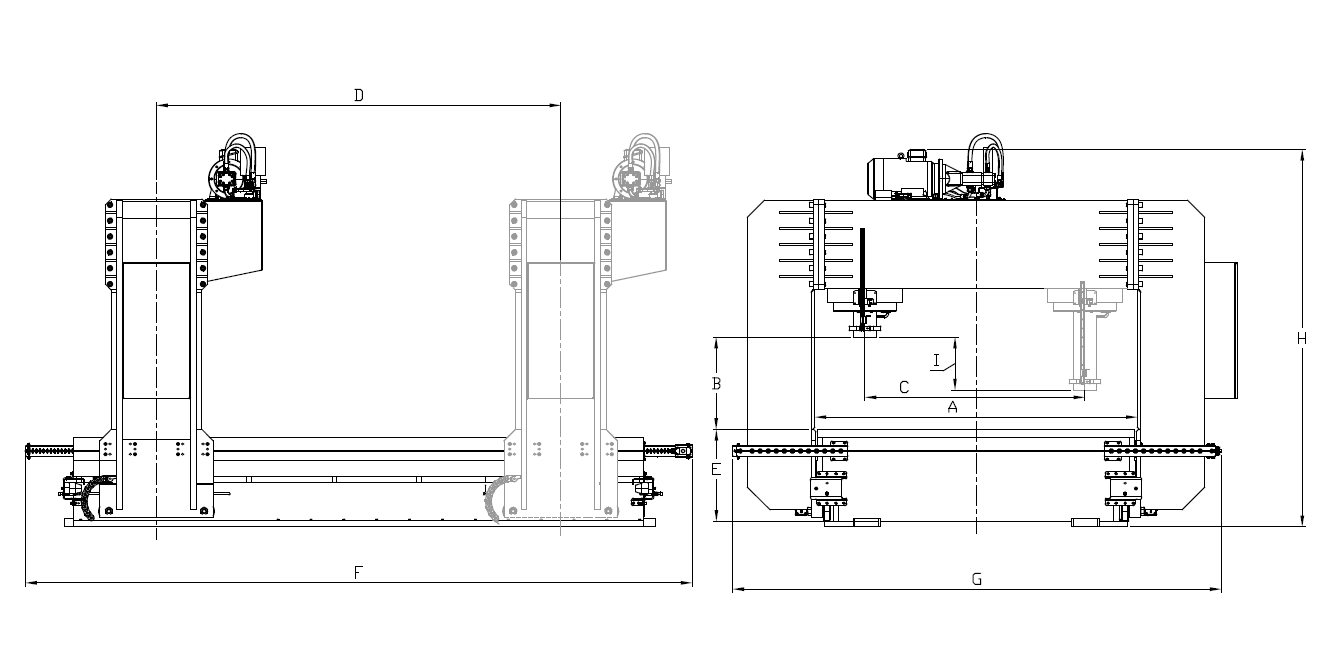

PPTLM-220 Dimensions

- A – Footprint – Side: 2050 mm

- B – Footprint – Front: 850 mm

- C – Useful Area – Side: 1350 mm

- D – Useful Area – Front: 2650 mm

- E – Vertical Daylight: 800 mm

- F – Total Length: 4000 mm

- G – Total Width: 3200 mm

- H – Overall Height: 3100 mm

- I – Piston Stroke: 460 mm

The PPTLM-220 is a 220-ton motorised portal press for straightening large, heavy structures. Featuring a movable frame and cylinder with CE-certified safety.