Introduction

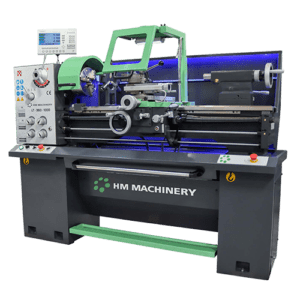

Welcome to our detailed guide on the key features of industrial metal lathes. In this blog, we delve into the specifications and capabilities of the LT Series metal lathes from HM Machinery, offering a comprehensive comparison to help you understand what sets each model apart. Furthermore, whether you’re a seasoned machinist or new to the world of metalworking, this guide aims to equip you with the knowledge to make an informed decision about which lathe best suits your needs. Moreover, read on to explore how these machines stand out in terms of precision, capacity, and versatility, ensuring you choose the perfect tool for your machining projects.

When choosing a workshop lathe, it’s essential to understand the technical specifications that affect its performance and suitability for different machining tasks. Also, in this blog, we explore the LT Series from HM Machinery, focusing on each model’s unique capabilities to help you decide which lathe best meets your specific needs.

Key Specifications Explained

Before we delve into the details, let’s clarify the most crucial specifications you should consider, and how they make the LT Series lathes versatile and reliable for a range of industrial applications.

Model-by-Model Feature Comparison

LT Series HM Machinery Industrial Metal Lathe (LT 250/550):

- Swing over bed: 250mm

- Distance between centers: 550mm

- Width of bed: 135mm

- Spindle bore: 26mm

- Voltage: 1x230V

- Motor: 1.1 kW

- Weight: 130kg

- Title Focus: Ideal for small to medium workshops looking for reliable and brand-specific machinery.

Large Capacity Metal Lathe (LT 360/1000):

- Swing over bed: 360mm

- Distance between centers: 1000mm

- Width of bed: 187mm

- Spindle bore: 52mm

- Voltage: 3x400V

- Motor: 1.5 kW

- Weight: 510kg

- Title Focus: Designed to handle larger projects with ease, offering stability and robust construction.

Variable Speed Metal Lathe for Machining Various Materials (LT 460/1000, LT 460/1500, LT 460/2000):

- Swing over bed: 460mm

- Distance between centers: 1000mm/1500mm/2000mm

- Width of bed: 300mm

- Spindle bore: 80mm

- Voltage: 3x400V

- Motor: 5.5 kW

- Weight: 1655kg/1820kg/1973kg

- Title Focus: Offers flexibility with variable speed controls to adapt to different materials and project requirements.

Precision Metal Lathe with Spindle Camlock (LT 460/1000):

- Further details emphasising the advanced spindle camlock feature that ensures high precision and reliability during operation.

Versatility in Threading

Each model in the LT Series is capable of cutting both metric and imperial threads, showcasing their versatility and making them suitable for various global industrial applications.

Targeted Applications and Industries

- Heavy-Duty Metal Lathe for Demanding Applications: For industries requiring durable and heavy-duty equipment.

- Metal Lathe for Machining Large & Elongated Workpieces: Ideal for handling large-scale industrial projects.

- Industrial Metal Lathe for Automotive & Aerospace Parts: Perfect for precision tasks in automotive and aerospace manufacturing.

- Heavy Equipment Metal Lathe: Best suited for heavy equipment manufacturing sectors.

- Technical School Metal Lathe for Advanced Machining: The go-to choice for educational institutions focusing on high-level machining skills.

- High-Precision Metal Lathe with Digital Readout: For users who prioritize accuracy and detailed readouts in their machining processes.

Comparison Chart

Selecting the right lathe is crucial for ensuring your machining operations meet the required standards of precision and efficiency. Below, we provide a detailed comparison chart of the LT Series metal lathes from HM Machinery. Additionally, this chart showcases diverse options ranging from compact models, ideal for smaller tasks, to robust machines capable of handling heavy-duty operations. Furthermore, by examining the specifications side by side, you can make an informed decision on which lathe best fits your needs. Explore the chart to understand the unique features and capabilities that each model has to offer.

| Model | Swing Over Bed (mm) | Distance Between Centers | Width of Bed | Spindle Bore | Spindle Taper | Power | Motor | Weight |

|---|---|---|---|---|---|---|---|---|

| LT 250/550 | 250 mm | 550 mm | 135 mm | 26 mm | MK-4 | 1-Ph x 230V | 1.1 kW | 130 kg |

| LT 360/1000 | 360 mm | 1000 mm | 187 mm | 52 mm | MK-6 | 3-Ph x 400V | 1.5 kW | 510 kg |

| LT 460/1000 | 460 mm | 1000 mm | 300 mm | 80 mm | MK-7 | 3-Ph x 400V | 5.5 kW | 1655 kg |

| LT 460/1500 | 460 mm | 1500 mm | 300 mm | 80 mm | MK-7 | 3-Ph x 400V | 5.5 kW | 1820 kg |

| LT 460/2000 | 460 mm | 2000 mm | 300 mm | 80 mm | MK-7 | 3-Ph x 400V | 5.5 kW | 1973 kg |

Each of these models is designed with the highest standards of precision and durability, ensuring that every lathe we offer is capable of meeting the demands of modern machining requirements. Similarly, for more information on our range of high-quality lathes, or to explore our full selection, please visit our Precision Metal Lathes product category.

Contact Us Today

Subsequently, if you have specific needs or questions regarding our lathes, feel free to contact us directly through our website. Our team is always ready to provide expert advice and support to help you find the perfect solution for your machining needs.