When it comes to metal fabrication applications, precision in bending operations is crucial. Whether working with mild steel, aluminum, or stainless steel, using the right C-Frame hydraulic press for metal bending and selecting the appropriate V-block width for metal bending are essential for achieving high-quality results and maintaining the durability of your tooling and machinery. In this comprehensive guide, we will explain how to calculate the required tonnage, choose the correct V-block width, and select the appropriate V-punch configuration. Using industry-standard mild steel for our calculations, we’ll also provide a comparative table of characteristics for common industrial metals. For further details, steel stockists often supply technical specifications on their websites to assist with material selection.

Tonnage Calculation for Bending Operations

Understanding Tonnage

Tonnage refers to the amount of force required to bend a given material. This is a critical factor to consider to ensure the bending machine can handle the operation without risking damage.

Tonnage Calculation Formula

To calculate the tonnage required for bending mild steel, we use the following formula:

Tonnage = (1.33 × UTS × W × T²) / D

Where:

- UTS is the Ultimate Tensile Strength of the material.

- W is the width of the plate.

- T is the thickness of the plate.

- D is the die opening.

Example Calculation with Mild Steel

For mild steel with an Ultimate Tensile Strength (UTS) of 450 MPa, bending a plate that is 260 mm wide and 10 mm thick using a die opening of 100 mm, the calculation would be:

- Plug in the values:

- Tonnage = (1.33 × 450 × 260 × 10²) / 100

- Simplify the equation:

- Tonnage = (1.33 × 450 × 260 × 100) / 100

- Tonnage = (1.33 × 450 × 260)

- Tonnage = 155,610 N

- Convert to metric tons (1 metric ton = 1,000 kg = 9.81 kN):

- Tonnage = 155,610 / 9810

- Tonnage ≈ 15.86 metric tons

- Thus, bending a 10 mm thick, 260 mm wide mild steel plate requires approximately 15.86 metric tons.

Choosing the Correct V-Block Width

The V-block width, or die opening, significantly impacts the required tonnage and the quality of the bend. The general rule of thumb is to use a die opening that is 8 to 10 times the material thickness for mild steel.

Die Opening Selection Guide

- For 1-3 mm thickness: 8T (T = thickness)

- For 4-10 mm thickness: 10T

- For 11-20 mm thickness: 12T

Using the earlier example of a 10 mm thick mild steel plate, a suitable die opening would be:

- Die Opening =10 × T = 10 × 10 = 100 mm

Choosing the Correct V-Punch Configuration

The V-punch configuration is crucial for achieving precise bends. The punch tip radius and angle must match the desired bend angle and radius.

Punch Selection Criteria

- Tip Radius: Should be equal to or slightly less than the desired bend radius.

- Punch Angle: Commonly 90 degrees for standard bending, but can vary depending on the required bend angle.

For a 90-degree bend with a 25 mm bend radius in a 10 mm thick mild steel plate:

- Tip Radius: 25 mm

- Punch Angle: 90 degrees

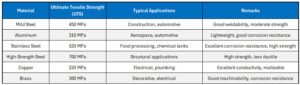

Comparative Characteristics of Common Industrial Metals

To help you choose the right material for your bending operations, here is a table comparing the characteristics of mild steel, aluminum, stainless steel, and other common industrial metals:

Conclusion

Accurate tonnage calculation, proper V-block width, and correct V-punch configuration are critical for successful bending operations in any metal fabrication application. At The Workshop Press Company, we provide a wide range of presses, including the versatile C-Frame hydraulic press for metal bending, designed to meet the needs of both industrial production and fabrication environments. For detailed product information, visit:

To view a comprehensive display of tools, visit: Hydraulic Press Accessories & Tooling Solutions

For further assistance in choosing the right machinery and configurations for your metal fabrication needs, feel free to contact us at 0800 999 1090 or visit our website at www.workshoppress.co.uk. Our team of experts is here to help you achieve optimal results in your projects. With our wide selection of C-Frame hydraulic presses and other metalworking machinery, we are equipped to meet all your bending and punching needs. Whether you’re looking for a high-capacity C-Press or a versatile C-Frame press, The Workshop Press Company offers the perfect solution for any metal fabrication application. Call us today to discuss your requirements and find the ideal press to meet your needs.