Frequently Asked Questions about Coil Feeding Systems

Coil Feeding Category

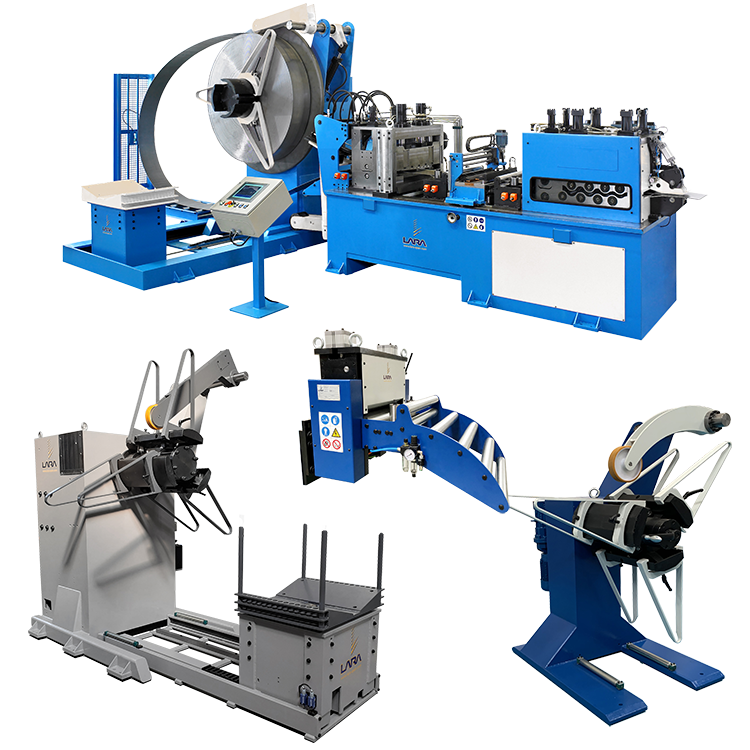

Q: “Coil feeding systems” typically include a reel, a feeder, and a straightener but not all three need to be together. Explain the function of each and how they integrate.

A: Function and Integration of Coil Feeding Components

Coil feeding systems are essential for automating the process of feeding material into presses. They typically include three main components:

– Reel (Decoiler): Holds and unwinds the coil of material. It can be either motorized or non-motorized and may have options for hydraulic or mechanical expansion to accommodate different coil sizes.

– Feeder: Accurately feeds the material into the press at a controlled rate. The feeder ensures precise positioning and timing, crucial for maintaining the quality of the stamping process.

– Straightener: Removes any curvature or coil set from the material before it is fed into the press, ensuring flat and consistent material is presented to the press.

These components can be integrated into a single compact unit or used independently, depending on the production requirements and available space.

A coil feeding system can be an technical decision so if you at any time need assistance in determining what type of equipment is required to suit your application, please contact us by email, web-form, text, or by phone. We have many years of experience and we will guide you to the right decision and support you after the purchase.

Q: What coil feeding systems are provided by The Workshop Press Company?

A: Coil Feeding Systems Offered

The Workshop Press Company provides a variety of coil feeding systems, including:

– AE Series: Electronic roll feeders for precise strip positioning.

– EMAE Series: Electronic straightener-feeders ideal for cyclical feeding and straightening of materials.

– DEMAE Series: Compact feeding lines for unwinding, straightening, and feeding in a single unit.

– DHP Series: Horizontal decoilers designed for light materials with minimal interruptions in production.

Q: What are the differences between the various systems offered?

A: Differences Between Coil Feeding Systems

The differences between the various systems offered by The Workshop Press Company include:

– Capacity: Each series can handle different maximum widths, thicknesses, and weights of coils.

– Functionality: Some systems are purely feeders, while others integrate straightening and feeding.

– Automation Level: Systems vary in their level of automation and control, from manual adjustments to advanced electronic controls with programming capabilities.

Q: How are coil feeding systems rated for capacity?

A: Rating of Coil Feeding Systems for Capacity

Coil feeding systems are rated based on:

– Maximum Coil Weight: The maximum weight the system can handle.

– Maximum Material Width and Thickness: The maximum width and thickness of the material the system can process.

– Feed Speed: The speed at which the system can feed the material into the press.

Q: What type of coil feeding system do I require?

A: Determining the Right Coil Feeding System

The type of coil feeding system you require depends on several factors:

– Material Specifications: The type, width, and thickness of the material you are working with.

– Production Requirements: The speed and accuracy required for your stamping process.

– Space Constraints: The available space in your facility for the equipment.

Q: Do I need to know the material type to determine the type of coil feeding?

A: Importance of Knowing Material Type

Yes, knowing the material type is essential as different materials have varying properties such as flexibility, hardness, and thickness, which affect the choice of feeding system.

Q: Do I need to know the width and thickness of the material I want to feed into my press?

A: Knowing Material Width and Thickness

Yes, it is crucial to know the width and thickness of the material to ensure the feeding system can handle the material dimensions and maintain precision in feeding.

Q: Will you sell me a feeding system without buying one of your presses?

A: Selling Coil Feeding Systems Independently

Yes, The Workshop Press Company sells coil feeding systems independently, and they can be integrated with your existing presses.

Q: Can you install a coil feeding system on one of my current presses?

A: Installing Coil Feeding Systems on Existing Presses

Yes, coil feeding systems can be installed on your current presses. Our team can assist with the integration process to ensure compatibility and optimal performance.

Q: How do you support a coil feeding system? Do you have staff or does the factory do it, or a combination of both methods?

A: Support for Coil Feeding Systems

Support is provided through a combination of in-house staff and factory support. This ensures comprehensive assistance, from installation and training to maintenance and troubleshooting.

Q: What is the warranty?

A: Warranty Information

The warranty details vary by product, but generally, The Workshop Press Company offers a standard 2-Year warranty that covers manufacturing defects and provides support for repairs and replacements.

Q: Do I need to know the diameter of the coils I want to feed into the coil feeding system?

A: Knowing Coil Diameter

Yes, knowing the diameter of the coils is necessary to ensure the system can accommodate the coils and function properly.

Q: Do I need to know the weight of the coil(s) I want to use?

A: Knowing Coil Weight

Yes, it is essential to know the weight of the coils to ensure the feeding system can support the load and operate safely and effectively.

Q: Is there a limit on the size of coils I can use either by weight, width, thickness, or length of coiled material?

A: Limits on Coil Size

Yes, there are limits on the size of coils, which include maximum weight, width, thickness, and length of the material. These limits are specified for each model to ensure safe and efficient operation.

Q: Can you help me determine what system I need?

A: Assistance in Choosing the Right System

Yes, our team can help you determine the most suitable system based on your specific requirements, including material type, production needs, and space constraints.

Q: What are the different types of systems offered?

A: Types of Coil Feeding Systems

The Workshop Press Company offers various types of coil feeding systems, including:

– Reels (Decoilers): For unwinding coils.

– Feeders: For accurate material feeding.

– Straighteners: For flattening material.

– Compact Lines: Integrating unwinding, straightening, and feeding.

Q: I have limited space for a coil feeding system. Can you suggest a compact feeding system?

A: Compact Feeding System Solutions

Yes, The Workshop Press Company offers compact feeding systems, such as the DEMAE series, which integrate unwinding, straightening, and feeding in a single unit, making them ideal for space-constrained environments.

Q: How much space is required for a coil feeding system?

A: Space Requirements for Coil Feeding Systems

The space required varies depending on the system model and configuration. Detailed dimensions and layout requirements are provided for each system to help you plan the installation.

Q: How does the tonnage of the press I have already or that I want affect the coil feeding system I need?

A: Impact of Press Tonnage on Coil Feeding System

The tonnage of the press affects the choice of coil feeding system as higher tonnage presses may require more robust feeding systems to handle larger and thicker materials efficiently. Matching the feeding system’s capacity with the press tonnage ensures optimal performance and safety.

Q: What is a re-coiler and what is its function in a coil feeding system?

A: Function of a Re-Coiler

A re-coiler is a machine used to wind the processed or leftover material back into a coil after it has been uncoiled, straightened, and fed through the press or other processing equipment. Its primary function is to efficiently manage the material post-processing, allowing for easy handling, storage, and further transportation or processing.

Q: What types of re-coilers are available from The Workshop Press Company?

A: Types of Re-Coilers Offered

The Workshop Press Company offers several types of re-coilers, including:

– Motorized Re-Coilers: These re-coilers use a motor to wind the material back into a coil, providing precise control over the tension and speed.

– Hydraulic Re-Coilers: Equipped with hydraulic systems for coil expansion and tension control, suitable for heavier and wider materials.

Q: How do I determine the right re-coiler for my application?

A: Selecting the Right Re-Coiler

The right re-coiler depends on several factors, including:

– Material Type: The type of material being recoiled (e.g., steel, aluminum, coated materials).

– Material Width and Thickness: The dimensions of the material.

– Coil Weight: The maximum weight of the coil the re-coiler can handle.

– Desired Speed and Tension Control: Requirements for winding speed and maintaining tension during recoiling.

Q: Can a re-coiler be integrated with my existing coil feeding system?

A: Integration with Existing Systems

Yes, re-coilers can be integrated with existing coil feeding systems. Compatibility will depend on the specifications of both the re-coiler and the current feeding system. The Workshop Press Company can provide assistance in ensuring proper integration.

Q: What are the maintenance requirements for re-coilers?

A: Maintenance Requirements

Regular maintenance of re-coilers includes:

– Inspection of Mechanical Components: Checking for wear and tear on gears, rollers, and hydraulic systems.

– Lubrication: Regular lubrication of moving parts to ensure smooth operation.

– Electrical and Control System Checks: Ensuring that all electrical components and control systems are functioning correctly.

Q: Do I need to know the diameter and weight of the coils for selecting a re-coiler?

A: Importance of Coil Diameter and Weight

Yes, knowing the diameter and weight of the coils is essential for selecting a re-coiler. This information ensures that the re-coiler can handle the physical dimensions and load capacity of the coils effectively.

Q: What safety features are included in re-coilers?

A: Safety Features in Re-Coilers

Re-coilers come with several safety features, including:

– Emergency Stop Buttons: For immediate shutdown in case of an emergency.

– Protective Guards and Shields: To prevent accidental contact with moving parts.

– Tension Control Systems: To prevent material breakage and ensure safe operation.

Q: Can you provide training and support for operating re-coilers?

A: Training and Support

Yes, The Workshop Press Company offers training and support services for operating re-coilers. This includes initial setup, operational training, and ongoing support to ensure efficient and safe use of the equipment.

Q: What is the warranty on re-coilers?

A: Warranty Information

The warranty on re-coilers typically covers manufacturing defects and parts replacement for a specified period. Detailed warranty terms are provided with the purchase of the equipment.

Q: Are custom re-coiling solutions available?

A: Custom Re-Coiling Solutions

Yes, custom re-coiling solutions are available to meet specific requirements. The Workshop Press Company can design and manufacture re-coilers tailored to unique material handling needs, space constraints, and production processes.

Q: How does the thickness and type of material affect the choice of re-coiler?

A: Impact of Material Thickness and Type

The thickness and type of material significantly impact the choice of re-coiler. Thicker and heavier materials require more robust re-coilers with higher tension control and load capacity. Different materials may also require specific handling features to avoid damage during recoiling.

Q: Can re-coilers handle materials with protective coatings?

A: Handling Coated Materials

Yes, re-coilers can handle materials with protective coatings. Optional features such as non-slip rollers and specialized guides are available to ensure that coated materials are handled gently without causing damage to the coating.

Q: How do you ensure the re-coiler maintains even tension during operation?

A: Ensuring Even Tension

Re-coilers maintain even tension through:

– Tension Control Systems: Automated systems that adjust the tension based on material properties and coil size.

– Hydraulic or Pneumatic Systems: For precise control of tension and speed during the recoiling process.

Q: What are the space requirements for installing a re-coiler?

A: Space Requirements for Re-Coilers

The space requirements for a re-coiler depend on the model and specifications. Detailed dimensions and layout plans are provided to ensure proper installation and operation within the available space.

Q: Can I use a re-coiler with multiple types of material?

A: Versatility of Re-Coilers

Yes, re-coilers can be used with multiple types of material, provided they are within the specified capacity limits. Adjustments may be needed to accommodate different material properties, such as thickness and width.

Coil Feeding Category