Hydraulic Presses - 80 Ton

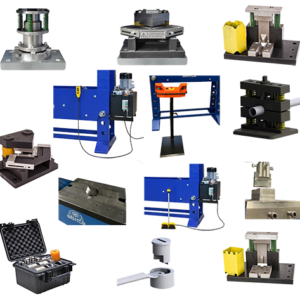

We offer an extensive range of 80 – 100 ton hydraulic presses, and below, all models from the 80 Ton Category are displayed. Each press is customisable and configurable to meet the customer’s specific applications and needs.

UK Expertise

1-3 Days Delivery

USA Sales

Nationwide Service

Ireland Sales

Fast Delivery to Ireland

Worldwide

Global ShippingWhat Characteristics define a Hydraulic Press?

Let’s first define the term “Hydraulic Press”.

According to Merriam-Webster a hydraulic press is: a machine in which great force with slow motion is communicated to a large plunger by means of liquid force into the cylinder in which it moves by a piston pump of small diameter to which the power is applied

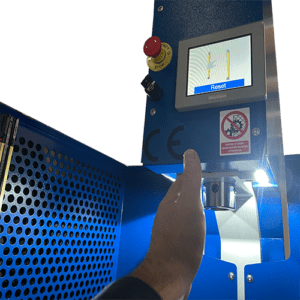

By all standard terms a hydraulic press has a frame, a hydraulic cylinder, a power pack or a pumping system, and a mechanism to control the power pack whether it be manual or electronically based.

The very first thing people talk about when discussing a hydraulic press is its Tonnage, and the tonnage of a hydraulic press typically ranges from 5 tons up to 5000 tons. In order to deliver the tonnage a Hydraulic Cylinder is needed, and the many different types of hydraulic cylinders is a complete topic on its own. Most importantly, all the presses that The Workshop Press Company offers are dual-action cylinders which means that hydraulic oil is delivered to both sides of the cylinder platen and which side the oil is delivered to is a matter of what side the controls are telling the power pack to deliver it to. In most situations, the larder the cylinder is, the more pressure it can deliver. There are other factors that can be introduced into the equation such as system pressure and oil delivery rate, but we are talking general terms now.

One of the other factors that defines the category of a hydraulic press is its Framework. The Workshop Press Company offers a variety of hydraulic presses, and the categories are Workshop Presses or H-Frame Presses, C-Frame Presses, Deep Drawing Presses, Four Column Presses, Portal Presses, and Production Presses. The details of the presses can be acquired in each product category on our site.

Other features that define a hydraulic press are the presses the size of the motor driving the hydraulic pump and it is defined in kilowatts. The Throat Depth which is the distance from the very front of the opening of the press to the back of the press and it defines how deep you can put a workpiece into the press. The Advance Speed which is how fast the cylinder advances until it switches into Working Speed, with Working Speed being slower than the Advance Speed. The Return Speed is how fast the cylinder returns after the define stroke or cycle is completed. System Pressure is defined in bar and most basic systems have a System Pressure around 300 bar. Piston stroke defines how far the piston can travel and this is defined by the overall size of the cylinder and piston. Some presses have Guides that assist in keeping the Slide Table perfectly square to the Bolster Table, and the larger the diameter is the more rigid the guides will be. The top table (Slide) and bottom table (Bolster) are defined by Length and Width and often times a thickness dimension will be included in defining the tables. The Daylight of a press defines what the maximum opening is from the Slide Table in its upmost position to the Bolster Table with the Bolster table being the static table. The Working Height of a press defines how hight the Bolster Table is from the floor. And finally there is the presses Length, Width, Height, and Weight. It is a generally accepted concept that the heavier the press is, the more rigid it is, but without question there are other factors that enter into that equation.

All these facts, figures, numbers, and parameters can be confusing so let the qualified people at The Workshop Press Company assist in determining the correct press for your application. Contact us on 0800 999 1090 or info@workshoppress.co.uk.