200 TON M/H-M/C-2 Motorised Hydraulic Workshop Press

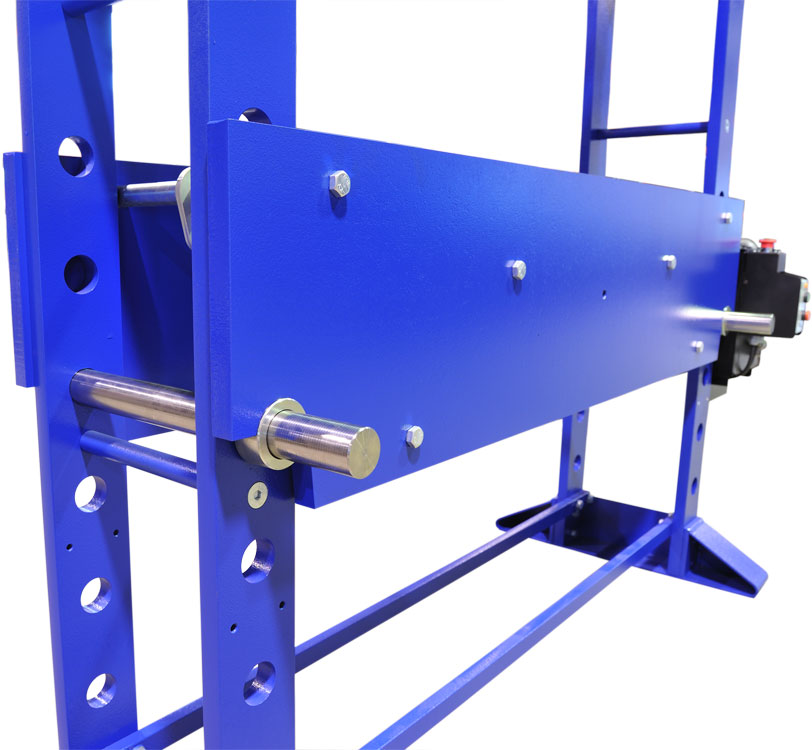

Product Code: 10085Seen here is our exceptional hydraulic workshop press, expertly crafted in the EU with a remarkable capacity of 200 tons (equivalent to 1962 kN). Thsi H Frame Press is constructed using premium-grade steel and hydraulic components, and this floor press ensures unparalleled durability and performance. It comes equipped with an adjustable cylinder, offering flexibility with left and right positioning, and a versatile working table measuring 1300mm in width, adjustable in vertical increments of 150mm. The primary cylinder boasts a top-of-the-line double-acting (dual-acting) mechanism.

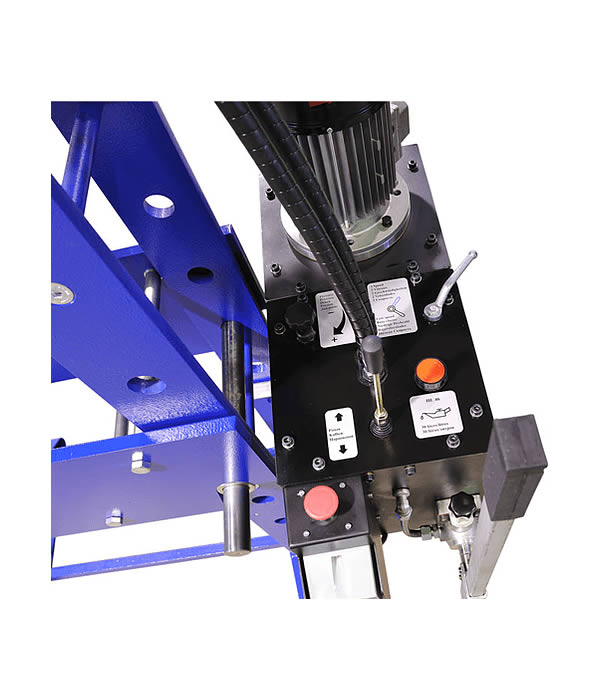

To facilitate precise control over pressing pressure, our press is accompanied by a pressure regulator. The main cylinder can be operated manually using a hand pump or, in motorized mode, with the convenience of a joystick. With two available speeds, effortlessly adjustable using a hand lever, you can effortlessly adapt to your specific requirements.

A Hydraulic Workshop Press is an indispensable machine for every factory or manufacturing facility that harnesses hydraulic power to compress materials across various applications. While hydraulic presses are available in a wide range of qualities, at The Workshop Press Company UK we pride ourselves in exclusively offering the finest RHTC hydraulic workshop presses.

Our Profi Motorised Workshop Presses are proudly manufactured in the EU, adhering to rigorous CE certification standards. As testament to their exceptional quality and reliability, these presses are readily available from our stock, accompanied by a generous 2-year warranty.

Please contact for prices

- Description

- Additional Info

Technical specifications

- Pressure force [kN]: 1962

- Maximum pressure [bar]: 243

- Piston stroke [mm]: 400

- Oil delivery [ltr/min]: 7.1/27.6

- Oil capacity [dm³]: 64

- Working speed [mm/sec]: 1.84

- Approaching speed [mm/sec]: 5.73

- Return speed [mm/sec]: 7.1

- Motor power [kW]: 3.0

- Voltage [V]: 400/3

- Frequency [Hz]: 50/60

- Revolutions per minute [rpm]: 3000

- Insulation protection [IP]: 54

- Working width [mm]: 1300

- Weight [kg]: 1690

Features

- Movable cylinder (left-right)

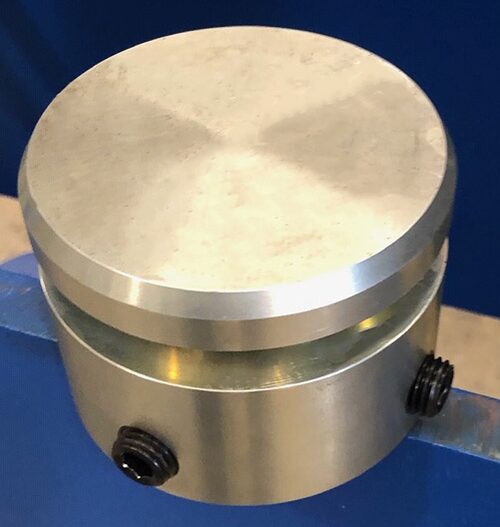

- Dual acting cylinder

- Integrated pressure manometer

- Pressure regulation

- Hydraulic unit with two speeds

- In height adjustable working table

- Joystick for the control of the piston

- Hand pump for precise press work

- 2 year warranty

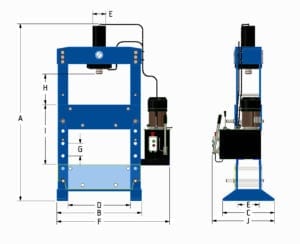

Dimensions

- A: 2270

- B: 1610

- C: 865

- D: 1300

- E: 410

- F: 1925

- G: 150

- H: 180

- I: 750

- J: 975

- K: 368

Diameters

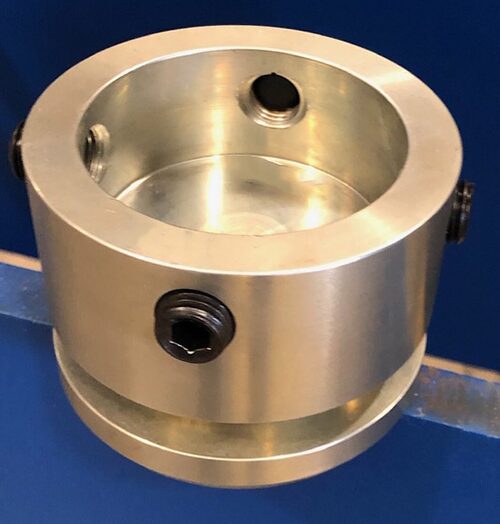

- Inside diameter of cylinder [mm]: 320

- Diameter of piston rod [mm]: 140

- Diameter of piston head [mm]: 175

Customisations & Modifcations

- 1-Phase Motor

- 60 Hz Motor

- Bespoke dimensions

- System Inetegrations

- Bespoke Applications

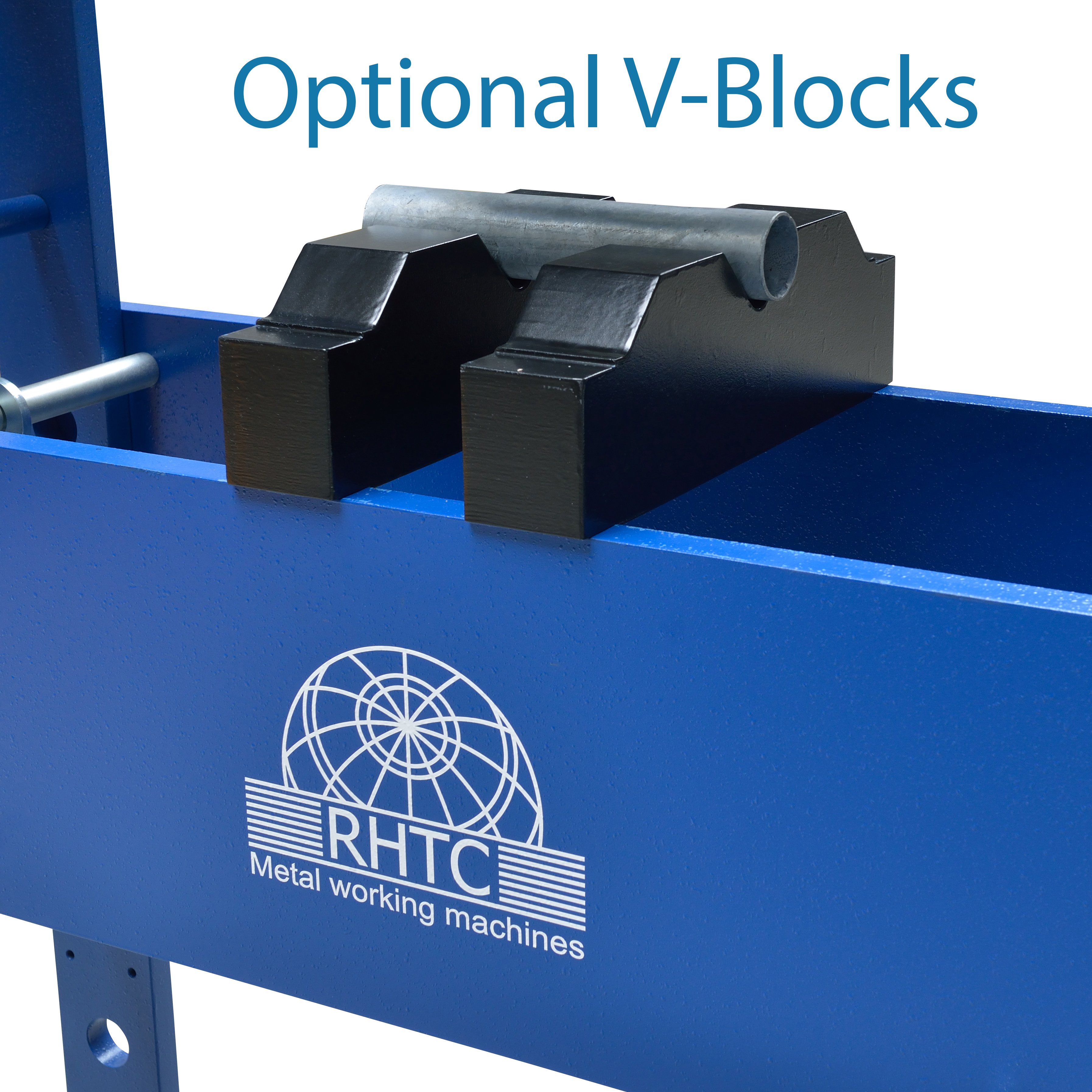

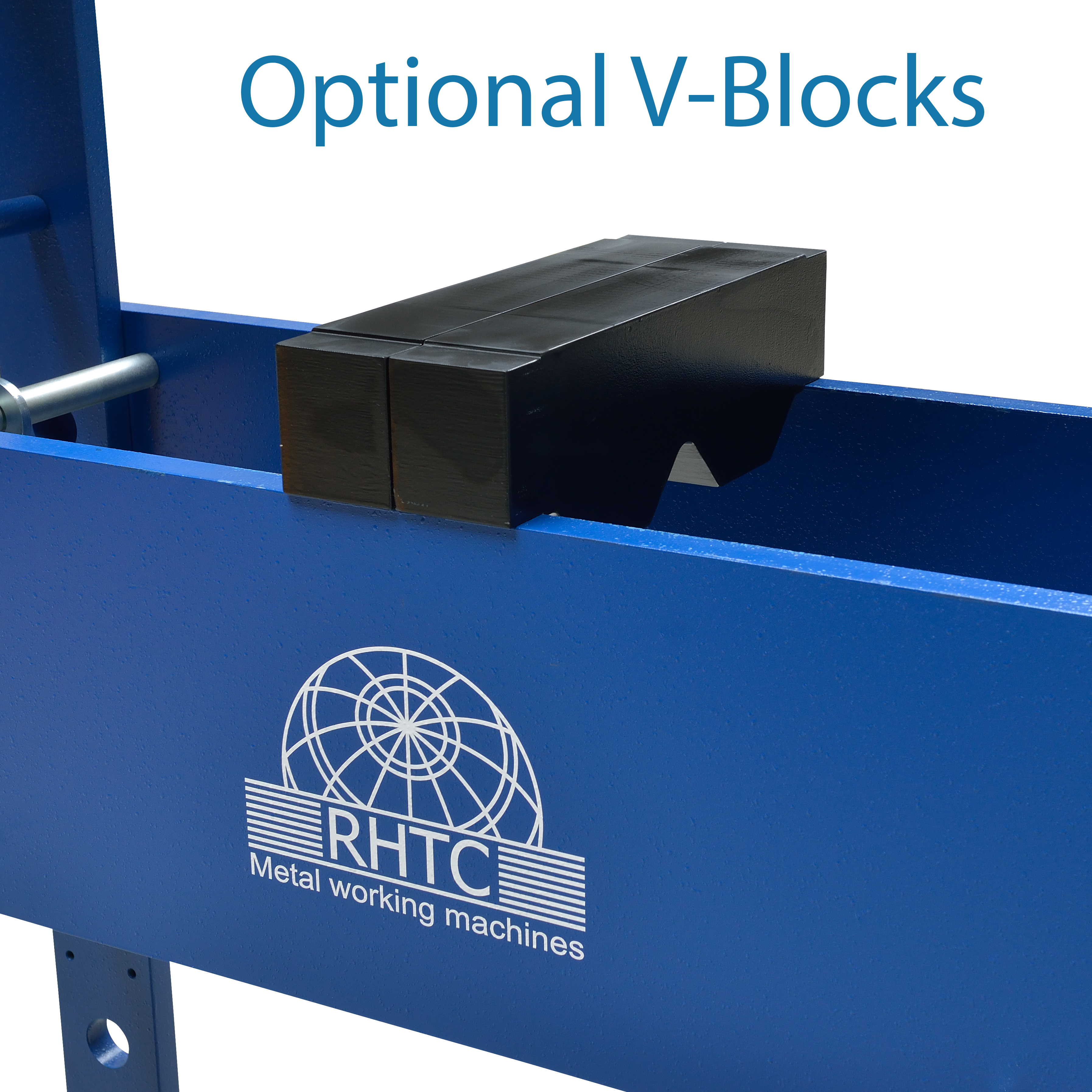

Optional Accessories & Tools

- V-Block sets

- foot pedals

- hand controls

- additional safety features

- system integrations

- mandrel sets

- corner rounding notchers

- corner wedge-shaped punches

- corner notchers

- hole punches of all shapes and sizes

- tube and pipe notching

- drain hole nibbler punch

- brake press tooling

- custom tools

Discover the Essence of a Workshop Press

A Workshop Press implements the power of hydraulics to compress and press materials across a diverse range of applications. While hydraulic presses exist in varying levels of quality, The Workshop Press Company UK exclusively offers premium-grade RHTC hydraulic workshop presses to the UK Market. Investing in an RHTC Hydraulic Press from us is a valuable contribution to your company’s profitability. Moreover, by incorporating hydraulic workshop press machinery into your workshop, maintenance, manufacturing, or assembly area, you unlock a world of expanded capabilities. Seamlessly perform a multitude of pressing processes, forming processes, folding, straightening, riveting, and other essential tasks. RHTC Profi Hydraulic Presses offer comprehensive functionality, durability, reliability, and stability. RHTC presses enable maximum utility and allow you to accomplish tasks efficiently, save time, and most importantly, save money and increase profits.

Endless Possibilities with a Workshop Press

Workshop Presses find their utility in a wide array of applications, revolutionizing your shop’s productivity. Some typical uses of shop presses include metalwork bending and folding, providing stability during welding projects, punching holes, straightening uneven metal parts, precise bearing pressing, flattening warped components, separating rusted parts, efficient compression, crushing used oil filters to remove excess oil, automobile part construction, jewelry-making, ammunition production, and bracket bending. The versatility of a Workshop Press knows no bounds, enabling you to conquer a diverse range of tasks with ease and precision.