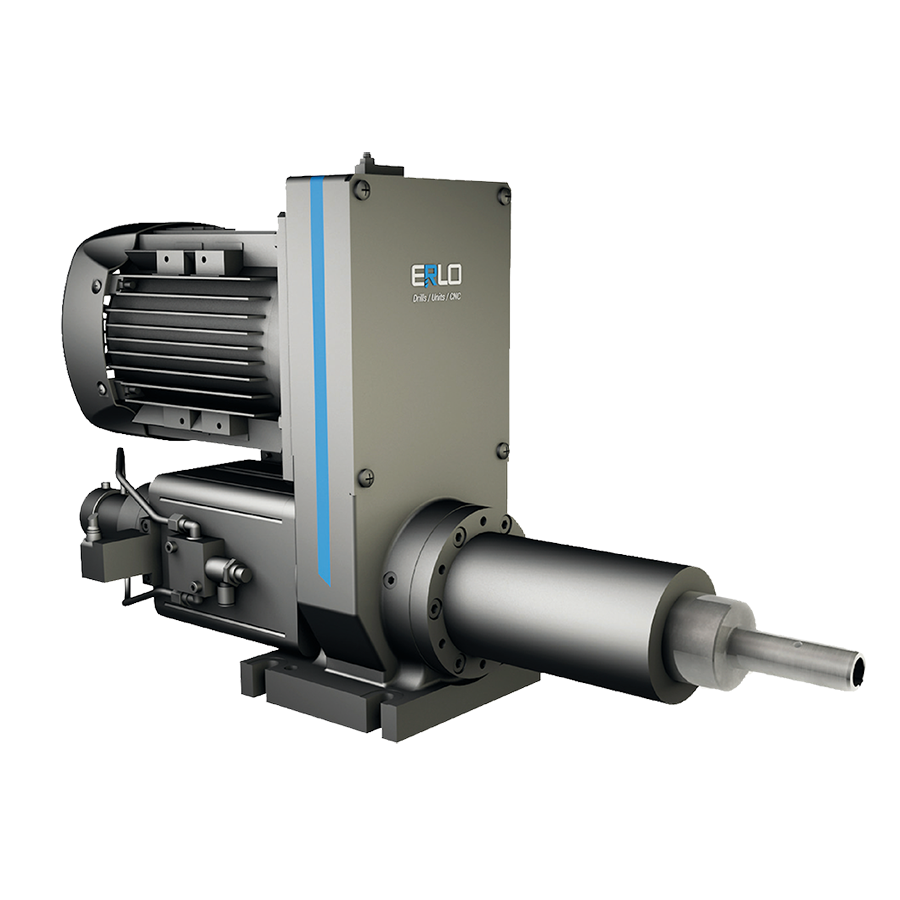

ERLO Autonomous Drilling Units: Precision Drilling and Bespoke Solutions

Product Code: ERLO-Autonomous-DrillsTo fully embrace the capabilities of ERLO's Autonomous Drilling Units offered by The Workshop Press Company UK, imagine a facility where efficiency, precision, and customization converge to meet both standard and unique manufacturing needs. These autonomous units are engineered for versatility, allowing for the transformation of any production line into a powerhouse of bespoke drilling solutions. With features designed to tackle intricate patterns and manage multiple workpieces simultaneously, each unit can be tailored to specific project requirements, ensuring a perfect fit for any task at hand.

Drawing upon the legacy of high-performance machinery, ERLO's Autonomous Drilling Units extend beyond traditional capabilities, offering advanced thread cutting functionality, compatibility with a wide range of tool holders, and exceptional drilling capacity across various materials. The units boast infinitely variable speed ranges and precision feeds within a design that maximizes space efficiency, ensuring that every aspect of your manufacturing process is optimized for peak performance.

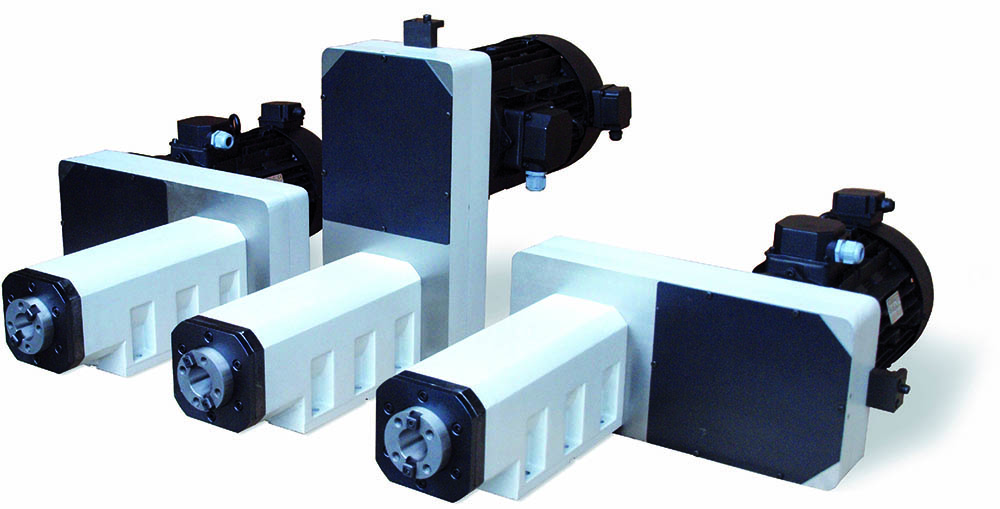

Moreover, the adaptability of ERLO's drilling technology is exemplified through its multi-head arrangements, capable of handling diverse materials with ease. This versatility is further enhanced by the option to select between manual or automatic feeds, providing smooth operation and precise control over every drilling task.

ERLO's Autonomous Drilling Units are more than just machines; they represent a partnership in manufacturing excellence, offering a pathway to overcome production challenges with advanced engineering solutions. By choosing ERLO through The Workshop Press Company UK, you align with a vision of manufacturing that prioritizes precision, efficiency, and tailor-made solutions to propel your operations forward.

For a comprehensive exploration of how ERLO's Autonomous Drilling Units can revolutionize your manufacturing capabilities, visit The Workshop Press Company UK. Our team of experts is dedicated to guiding you through the vast array of options, ensuring you find the ideal configuration to meet your specific production needs, whether it involves heavy-duty applications or intricate metal drilling tasks.

Please contact for prices

- Description

- Additional Info

CG Series Autonomous Drill Machines Summary

- CG.16

- Drilling Capacity in Steel (700 N/mm²): Ø 16 mm

- Tapping Capacity in Steel (700 N/mm²): M12

- Revolutions Range (50 Hz): 210—9000 rpm

- Maximum Turning Torque: 31 Nm

- Spindle Cone: ISO 30 DIN 2080

- Weight (without motor): ~40 Kg

- Motors Available (50 Hz): 750 rpm / 0.55 kW, 1500 rpm / 1.5 kW, 3000 rpm / 2.2 kW

- CG.40

- Drilling Capacity in Steel (700 N/mm²): Ø 40 mm

- Tapping Capacity in Steel (700 N/mm²): M24

- Revolutions Range (50 Hz): 322—2175 rpm

- Maximum Turning Torque: 228 Nm

- Spindle Cone: ISO 40

- Weight (without motor): ~100 Kg

- Motors Available (50 Hz): 1000 rpm / 5.5 kW, 1500 rpm / 7.5-11 kW

- CG.50

- Drilling Capacity in Steel (700 N/mm²): Ø 80 mm

- Tapping Capacity in Steel (700 N/mm²): M42

- Revolutions Range (50 Hz): 380—1475 rpm

- Maximum Turning Torque: 540 Nm

- Spindle Cone: ISO 50

- Weight (without motor): ~300 Kg

- Motors Available (50 Hz): 990 rpm / 22 kW, 1475 rpm / 22 kW

Key Features

- Modular Assembly: These units are designed for modular assembly, providing flexibility for various machining setups.

- Optional Equipment: Includes encoder for rigid tapping and tool positioning, rotary joint for tool internal cooling, and combinations of both with protection bellows for slide guides.

- Combinable Elements: Various elements like slides, columns, multispindle heads, and tool holders can be combined with these units for customized solutions.

Revolver Heads

Revolver heads are designed to integrate seamlessly into machining units, offering enhanced flexibility and efficiency for various machining operations.

- UR160

- Maximum Positions Number: 6

- Torque Transmissible to Spindle: 80 Nm

- Max. RPM Spindle: 12,000

- Spindle Positioning Accuracy: +/-3”

- Motor Power: 4 kW

- Turning Time One Position: 0.9 sec

- Crown Diam. Hirth: 160 mm

- Weight: 35 kg

- Available Spindle Type: ABS, HSK, ER, DIN 55058

- UR200 / UR250

- Maximum Positions Number: 6 / 6-8

- Torque Transmissible to Spindle: 200 / 300 Nm

- Max. RPM Spindle: 10,000

- Spindle Positioning Accuracy: +/-3”

- Motor Power: 5 / 6.5 kW

- Turning Time One Position: 1.0 sec

- Crown Diam. Hirth: 200 / 250 mm

- Weight: 60 / 140 kg

- Available Spindle Type: ABS, HSK, ER, DIN 55058

- UR360

- Maximum Positions Number: 6/8/12

- Torque Transmissible to Spindle: 800 Nm

- Max. RPM Spindle: 8,000

- Spindle Positioning Accuracy: +/-3”

- Motor Power: 16 kW

- Turning Time One Position: 1.5 sec

- Crown Diam. Hirth: 350 / 360 mm

- Weight: 300 kg

- Available Spindle Type: ABS, HSK, ER, DIN 55058

Key Features include:

- Oil circuit for locking and unlocking of the revolver headstock (F1).

- Cooling entry for tools (F2).

- Fixation holes of the revolver headstock (F3).

- Oil-air entry (F4).

- Electric connector (F5).

Comparison of CG Series Drill Machines and Revolver Heads

The CG Series Drill Machines are autonomous, precision drilling units designed for high-performance operations with modular assembly and advanced customization options. They excel in diverse machining setups, offering flexibility with drilling and tapping capabilities for various materials.

In contrast, Revolver Heads are specialized components that integrate into machining units, providing enhanced efficiency and flexibility with multi-position spindles for complex operations. They are ideal for tasks requiring quick spindle changes and high torque transmission, ensuring precision and adaptability in demanding production environments.

Erlo: Tradition and Innovation in Drilling and Tapping Machines

Erlo is a renowned manufacturer of drilling and tapping machines, boasting over 50 years of industry experience. Known for producing reliable and durable machines, Erlo ensures high quality through the use of premium materials and components. Their machines are also user-friendly and easy to maintain, making them an excellent choice for machinists and metal fabricators of all experience levels.

In addition to their standard range of drilling and tapping machines, Erlo offers customized solutions tailored to specific applications. These bespoke designs are created with a thorough understanding of customer needs, ensuring the machines meet exact requirements.

At Erlo, tradition and innovation are considered inseparable. They are committed to providing customers with the latest technology while upholding the timeless values of craftsmanship and quality.

Why Choose Erlo?

If you’re looking for a dependable and cutting-edge drilling or tapping machine, Erlo is the perfect choice.

Contact us today to learn more about our products and services.

Erlo products are proudly sold in the UK by:

The Workshop Press Company

Kenilworth, Warwickshire