AX.35 and AX.40 Floor Standing Industrial Drilling Machines from ERLO

Product Code: AX-SERIES-ERLOThe AX Series Pillar Drills, including the AX.35 and AX.40 models, feature automatic feed with a mechanical clutch, providing superior control and precision. Their geared drive systems ensure reliable performance, while high-quality steel gears offer durability. Key features include a depth scale, adjustable depth stop, thermomagnetic switch, emergency STOP, and spindle reversing switch. The integrated coolant equipment and worklight enhance operational efficiency. Suitable for a variety of industrial drilling applications, the AX Series is a versatile addition to any workshop.

Please contact for prices

- Description

- Additional Info

The AX.35 and AX.40 models from ERLO’s AX Series are designed to handle demanding industrial drilling tasks with precision and efficiency. These machines are equipped with automatic feed via a mechanical clutch, providing operators with ease of operation, especially for repetitive tasks. The AX Series offers a middle ground between manual models like the SX Series, which provide full operator control, and the BX Series, which utilize an electromagnetic clutch for fully automated feed.

The AX.35 and AX.40 are ideal for industries requiring robust machines capable of handling heavy workloads, while still allowing operators some control over the drilling process. The machines offer significant improvements in efficiency compared to manual feed models, without the full automation of the BX Series.

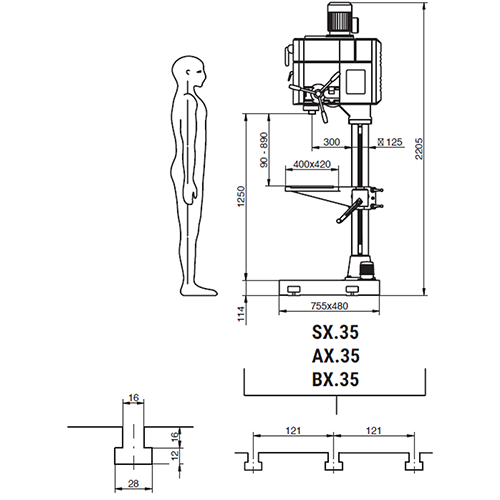

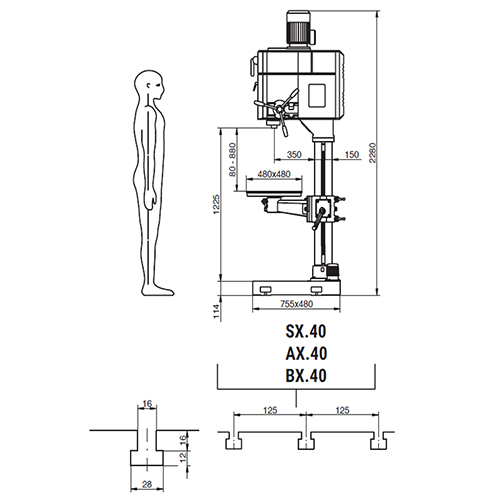

| AX.35 | AX.40 | |

|---|---|---|

| Max Drill Cap. (Steel) [mm] | 35 | 40 |

| Max Drill Cap. (Cast Iron) [mm] | 40 | 45 |

| Max Tap Cap. (Steel) [mm] | M27 | M33 |

| Max Tap Cap. (Cast Iron) [mm] | M33 | M39 |

| Morse Taper | MT4 | MT4 |

| Max Spindle Stroke [mm] | 150 | 175 |

| Main Motor Power [HP (kW)] | 2 (1.5) | 3 (2.2) |

| Coolant Pump Power [HP (kW)] | 0.10 (0.07) | 0.10 (0.07) |

| No. of Speeds | 9 | 9 |

| Speed Range [rpm] | 132-1852 | 132-1852 |

| Table Dimensions [mm] | 400×420 | 480×480 |

| Column Diameter [mm] | 125 | 150 |

| Spindle to Column [mm] | 300 | 350 |

| Net Weight [kg] | 400 | 490 |

ndustries Using the Machine and Their Uses:

- Manufacturing: Precision drilling and tapping

- Metalworking: Fabrication and machining

- Automotive: Engine and component manufacturing

- Aerospace: Component drilling and assembly

- Construction: Structural and material preparation

Optional Extras

- Electronic speed variator with digital speed reader

- Depth digital reader for precise depth control

- Manual tapping system (IR/RS)

- Rotating and tilting table (MGI) for increased flexibility

- Pneumatic counterbalance for rapid spindle approach and return

- Electronic speed variator with digital speed reader

- Depth digital reader

- Manual tapping system (IR/RS)

- Rotating and tilting table (MGI)

- Pneumatic counterbalance for rapid approach and retract

Pillar Drills Tailored To Your Workspace

- Versatile Applications: Our range includes everything from the workshop drill to industrial drills for sale, ensuring we have the perfect fit for your metalworking, woodworking, or any other drilling requirement.

- Customisation & Accessories: With adjustable and tilt-able worktables, plus a variety of tooling options, our machines are as adaptable as they come. Popular accessories include vices, collets, and chucks, enhancing your machine’s versatility.

- Safety & Compliance: Safety is our top priority. All models are CE certified, featuring separate emergency stops for worry-free operation.

Why Choose Workshop Press For Your Pillar Drill?

- Unmatched Quality: Every drill machine we offer is built to the highest standards, ensuring you get a product that not only meets but exceeds expectations.

- Industry Expertise: Leverage our expertise to find the ideal drill for sale that meets your specific needs, backed by our comprehensive after-sales support.

- Competitive Pricing: Get the best value for your investment with our competitively priced range, designed to last and backed by a 2-Year Warranty.

Pillar Drill Presses: The Essential Tool for Precision and Power

Whether you’re searching for the best drill to enhance your DIY projects or an industrial pillar drill UK businesses rely on for heavy-duty tasks, Workshop Press is your go-to destination. Discover how our machines bring unparalleled accuracy and efficiency to your work.

Differentiating Between Professional and Industrial Pillar Drills

When differentiating between a professional and an industrial pillar drill press, it’s important to consider their intended use, construction, and capabilities. Industrial pillar drills are specifically designed for heavy-duty applications and continuous use in demanding environments such as metal fabrication shops and manufacturing plants. They feature powerful motors, advanced gear-driven mechanisms, and enhanced durability to handle larger drill bits and tougher materials with precision and reliability. In contrast, professional pillar drills are built for regular but not continuous use, offering robust construction and user-friendly features suitable for workshops, small businesses, and educational institutions. Understanding these distinctions helps in selecting the right drill press for your specific needs.

Read our post about Pillar Drill Presses and the importance of investing in quality to optimise durability and longevity in your workshop by clicking HERE.

Ready to Elevate Your Drilling Capabilities?

Browse our selection today and find the pillar drill that’s right for you.

For queries or to discuss your specific needs, don’t hesitate to get in touch.

Call us toll-free at 0800 999 1090. Let’s drill down to precision together with Workshop Press.

High-performance AX Series Automatic Feed Pillar Drills with mechanical clutch and geared drive, ideal for precision industrial drilling.