- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

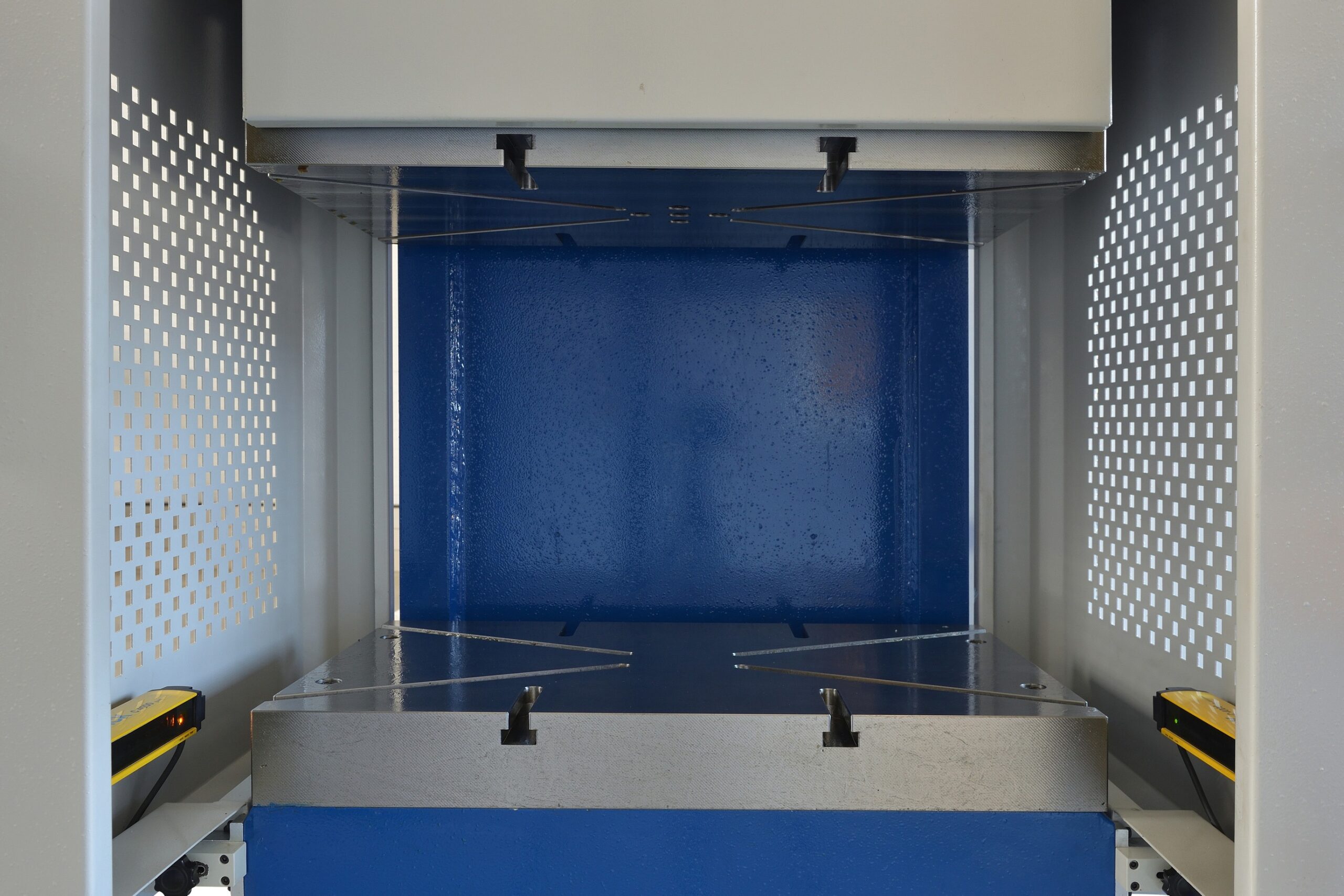

C-Frame Press • PPCBT-60 • 60 Ton • Upper Table • Lower Table • **In Stock**

Product Code: PPCTB-60The Profi Press PPCTS-60 is a high-performance 60-ton hydraulic press designed for precision metalworking and industrial applications. Engineered with a robust welded steel frame, safety light barriers, and an efficient hydraulic system, this press delivers superior force and accuracy. Equipped with a 500x500 mm table size and a 400 mm stroke, it ensures versatility and reliability for various pressing tasks. Built for safety, efficiency, and durability, it is ideal for workshops, manufacturing plants, and industrial applications.

Please contact for prices

- Description

- Additional Info

The Profi Press PPCTS-60 hydraulic press offers exceptional performance with a 60-ton pressure force, making it an excellent choice for precision metalworking, forming, and pressing operations. It features a ram cylinder diameter of 175 mm and an adjustable stroke length of 400 mm, ensuring adaptability for different tasks. With a motor power of 3 kW, a 75-liter oil tank, and an efficient hydraulic system, this press provides consistent and reliable performance. The automatic and manual operation modes, coupled with safety light barriers, enhance operator safety. Built with a sturdy welded steel frame, this machine guarantees longevity and stability.

Technical Specifications

- Pressure Force [ton]: 60

- Table Size [mm]: 500 x 500

- Stroke Length [mm]: 400

- Day Light [mm]: 500

- Ram Cylinder Diameter [mm]: 175

- Ram Cylinder Down Speed [mm/sec]: 12

- Ram Cylinder Return Speed [mm/sec]: 12

- Ram Cylinder Working Speed [mm/sec]: 4

- Motor Power [kW]: 3

- Hydraulic Pump Capacity [liters]: 12+6

- Oil Tank Capacity [liters]: 75

- Max Working Pressure [bar]: 260

- Min Working Pressure [bar]: 30

Key Features

- 60-ton pressure force for heavy-duty applications

- 500×500 mm work table with strong steel construction

- Automatic and manual operation modes

- Two-hand operation module for enhanced safety

- Safety light barriers for accident prevention

Optional Accessories

- Custom press tools

- Additional safety covers

- Foot pedal for hands-free operation

- Specialized hydraulic oils

- Pressure control unit

The Profi Press PPCTS-60 is a 60-ton hydraulic press with a 500×500 mm table size, 400 mm stroke, and 260-bar maximum pressure. It features a two-hand operation module, safety light barriers, and a rugged steel frame for safe and efficient operation.