- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

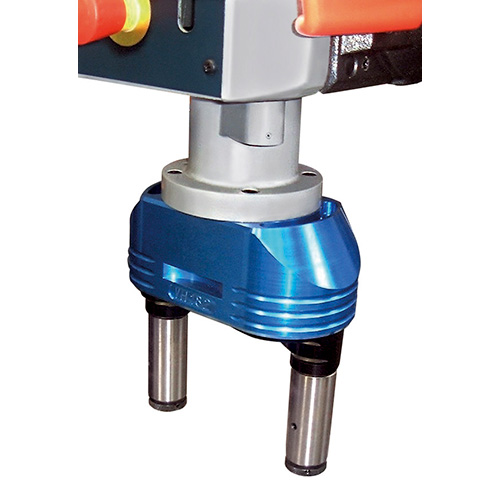

Drill Heads – Precision Multi-Spindle Drill Heads for Industrial Applications

Product Code: Erlo-Dual Drill Multi Drill CM2The Multi-Spindle Drill Head Attachment is a game-changer in multi-tasking drilling operations, capable of holding multiple drill bits simultaneously for unparalleled efficiency. The adjustable width between tool holders can be customized to meet specific customer requirements, making it a versatile solution for diverse drilling needs in industrial environments. At The Workshop Press Company UK, we offer a range of sizes and models to suit your specific applications. Contact us today to determine the best solution for your requirements.

Please contact for prices

- Description

- Additional Info

Differences Between Drill Head Models

- Spindle Count: Models range from 2 to 4 spindles.

- Center Distance: Varies from 12 mm to 253 mm depending on the model.

- Drilling Capacity: Models support different drilling capacities, ranging from 1 mm to 25 mm.

- Tapping Capacity: Tapping capabilities range from M3 to M20.

- Max RPM: Speeds vary from 2,000 to 4,000 RPM depending on the model.

- Weight: Models weigh between 0.95 kg and 23.7 kg.

Technical Specifications

- Spindle Count: 2-4 spindles depending on the model.

- Center Distance: Ranges from 12 mm to 253 mm.

- Drilling Capacity: 1 mm to 25 mm in steel.

- Tapping Capacity: M3 to M20.

- Max RPM: 2,000 to 4,000 RPM.

- Weight: 0.95 kg to 23.7 kg.

Features and Uses

- Multi-spindle configurations for simultaneous drilling and tapping operations.

- High-speed drilling with RPM up to 4,000.

- Accurate tool holding and easy attachment to drill presses.

- Flexible center distance settings for various applications.

- Durable construction for long-lasting performance in industrial settings.

Industries Using the VH Series

- Automotive: Precision drilling for engine components and other parts.

- Aerospace: Tapping and drilling in lightweight alloys for aerospace parts.

- Metal Fabrication: Suitable for sheet metal and structural component processing.

- General Machining: Multi-purpose use for custom machining tasks.

Pertinent Information

- Applications: Suitable for precision drilling and tapping in metal fabrication, automotive, aerospace, and general machining industries.

- Customization: VH series models offer customization in spindle count, center distances, and tapping capacities.

- Durability: Made with high-quality materials for long service life and precision.

| Model | Spindle Count |

Center Distance (Min-Max) |

Drilling Capacity |

Tapping Capacity |

Max RPM |

Weight |

|---|---|---|---|---|---|---|

| VH 042 | 2 | 12 mm – 72 mm | 4 mm | M3 | 4,000 | 0.95 kg |

| VH 043 L | 3 | 12 mm + 12 mm 42 mm + 42 mm |

4 mm | M3 | 4,000 | 1.05 kg |

| VH 043 | 3 | 0 mm – 785 mm | 4 mm | M3 | 4,000 | 1.4 kg |

| VH 044 | 4 | 0 mm – 895 mm | 4 mm | M3 | 4,000 | 1.9 kg |

| VH 062 | 2 | 17 mm – 93 mm | 6 mm | M5 | 4,000 | 1.65 kg |

| VH 063 L | 3 | 175 mm + 175 mm 555 mm + 555 mm |

6 mm | M5 | 4,000 | 1.95 kg |

| VH 063 | 3 | 0 mm – 103 mm | 6 mm | M5 | 4,000 | 2.3 kg |

| VH 064 | 4 | 0 mm – 117 mm | 6 mm | M5 | 4,000 | 3.1 kg |

| VH 082 | 2 | 24 mm – 108 mm | 8 mm | M6 | 4,000 | 2.2 kg |

| VH 083 L | 3 | 24 mm + 24 mm 66 mm + 66 mm |

8 mm | M6 | 4,000 | 2.9 kg |

| VH 083 | 3 | 0 mm – 120 mm | 8 mm | M6 | 4,000 | 3.4 kg |

| VH 084 | 4 | 0 mm – 137 mm | 8 mm | M6 | 4,000 | 4.6 kg |

| VH 102 | 2 | 28 mm – 120 mm | 10 mm | M8 | 3,500 | 3.5 kg |

| VH 103 L | 3 | 28 mm + 28 mm 74 mm + 74 mm |

10 mm | M8 | 3,500 | 4.9 kg |

| VH 103 | 3 | 0 mm – 132 mm | 10 mm | M8 | 3,500 | 4.9 kg |

| VH 104 | 4 | 0 mm – 152 mm | 10 mm | M8 | 3,500 | 7.2 kg |

| VH 132 | 2 | 35 mm – 151 mm | 13 mm | M10 | 3,000 | 5.3 kg |

| VH 133 L | 3 | 35 mm + 35 mm 93 mm + 93 mm |

13 mm | M10 | 3,000 | 7.2 kg |

| VH 133 | 3 | 0 mm – 167 mm | 13 mm | M10 | 3,000 | 7.7 kg |

| VH 134 | 4 | 0 mm – 191 mm | 13 mm | M10 | 3,000 | 10.8 kg |

| VH 181 | 2 | 41 mm – 173 mm | 18 mm | M14 | 2,500 | 8.3 kg |

| VH 182 | 2 | 41 mm – 173 mm | 18 mm | M14 | 2,500 | 10.75 kg |

| VH 183 L | 3 | 41 mm + 41 mm 107 mm + 107 mm |

18 mm | M14 | 2,500 | 12 kg |

| VH 183 | 3 | 0 mm – 191 mm | 18 mm | M14 | 2,500 | 15.75 kg |

| VH 184 | 4 | 0 mm – 218 mm | 18 mm | M14 | 2,500 | 19.75 kg |

| VH 201 | 2 | 45 mm – 184 mm | 20 mm | M16 | 2,500 | 9.2 kg |

| VH 202 | 2 | 45 mm – 184 mm | 20 mm | M16 | 2,500 | 12.3 kg |

| VH 203 L | 3 | 45 mm + 45 mm 110 mm + 110 mm |

20 mm | M16 | 2,500 | 13.8 kg |

| VH 203 | 3 | 0 mm – 206 mm | 20 mm | M16 | 2,500 | 17.3 kg |

| VH 204 | 4 | 0 mm – 229 mm | 20 mm | M16 | 2,500 | 21.3 kg |

| VH 251 | 2 | 50 mm – 208 mm | 25 mm | M20 | 2,000 | 10.7 kg |

| VH 252 | 2 | 50 mm – 208 mm | 25 mm | M20 | 2,000 | 13.7 kg |

| VH 253 L | 3 | 50 mm + 50 mm 110 mm + 110 mm |

25 mm | M20 | 2,000 | 15.7 kg |

| VH 253 | 3 | 0 mm – 229 mm | 25 mm | M20 | 2,000 | 19.7 kg |

| VH 254 | 4 | 0 mm – 253 mm | 25 mm | M20 | 2,000 | 23.7 kg |

How These Devices Attach to the Drill Press

The VH series heads are designed to be compatible with standard pillar drills using several standardized attachment methods to ensure secure and efficient operation. The attachment mechanisms follow DIN standards, which dictate the type of tooling interfaces that can be used. Below is an explanation of the DIN standards that are applicable and how they affect the attachment of the device to the drill press:

DIN 238: Drill Sleeves

DIN 238 specifies the dimensions and characteristics of drill sleeves, which are used to adapt drill heads to fit different spindle diameters. These sleeves enable the use of drills with smaller shank sizes in larger spindles, ensuring compatibility across various tool sizes without compromising stability. The drill sleeve is inserted into the drill’s spindle, providing a precise fit for the VH series heads, ensuring they stay securely in place during operation.

- Key Benefits of DIN 238: Allows flexibility in adapting different drill sizes to the machine.

- Ensures compatibility between spindle and head, accommodating various tool diameters.

DIN 55058: Spring Collet Chucks

DIN 55058 governs the design of spring collet chucks, which are used to hold tools in place with high precision and rigidity. The collet chucks ensure the tool is centered correctly and held tightly within the spindle, minimizing runout and ensuring consistent drilling and tapping operations. The collet chucks are particularly useful for high-speed drilling operations, as they provide excellent tool retention even under high RPMs.

- Key Benefits of DIN 55058: Precise tool holding for high-accuracy drilling and tapping.

- Reduced tool runout, ensuring higher quality of drilled or tapped holes.

DIN 228: Steep Taper Tool Holders

DIN 228 specifies the dimensions and taper angles of steep taper tool holders, commonly used for high-torque drilling applications. These holders fit securely into the spindle of the drill press with a taper that self-locks when torque is applied. This system ensures that the VH series heads remain firmly in place during heavy-duty operations, preventing slippage or detachment under load.

- Key Benefits of DIN 228: Strong and secure attachment, especially in high-torque situations.

- Quick and easy tool changes, minimizing downtime.

Installation and Setup

The VH series heads are designed for quick and easy installation on standard drill presses. The heads are typically attached using a combination of the above-mentioned DIN-compliant tool holders, depending on the specific setup of the drill press. The entire process is streamlined to ensure minimal downtime when switching between heads, allowing for efficient, multi-spindle drilling operations.

- Quick Installation: Tooling interfaces like collet chucks and drill sleeves allow for rapid installation of the VH series heads. Operators can swiftly change out heads as needed, enabling different operations without significant delays.

- Easy Setup: Once the appropriate attachment method (sleeve, collet chuck, or steep taper) is selected, aligning and securing the VH series head is straightforward. This ensures repeatability in positioning and operational accuracy.

Explore the versatile and complete series of Drill Heads, available in multiple models for customized drilling solutions. With multi-spindle configurations and precise DIN standard attachments, these drill heads are designed for high-efficiency industrial applications.