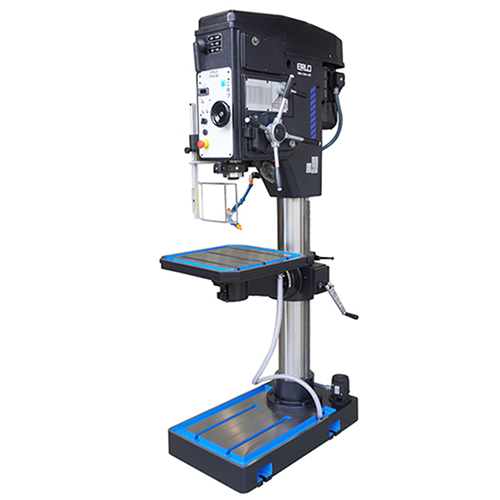

TH Series Floor Standing Industrial Column Drill from ERLO

Product Code: TH-SERIES-ERLO"Discover our exceptional range of Round Column Pillar Drilling Machines, designed to deliver unmatched performance and precision in your drilling operations. We offer two distinct models to meet your specific requirements, each equipped with advanced features and built to the highest standards of quality.

Introducing our 40 to 50 mm Drill of Round Column Mechanical Automatic Feed, a powerhouse that combines efficiency and versatility to elevate your drilling capabilities. With its mechanical automatic feed system, you can effortlessly maintain a steady and consistent drilling pace, saving you time and effort.

The robust transmission gears ensure optimal power transmission, allowing for smooth and precise drilling operations.

Experience enhanced flexibility with the moveable table and fixed bit, allowing you to position your materials precisely and securely.

Please contact for prices

- Description

- Additional Info

The TH Series Industrial Column Drills from ERLO are designed to provide precision and durability in demanding industrial applications. The series is divided into two distinct models—THI and THV, each offering unique features tailored to different operational needs:

- THI Models:

- Equipped with an electromagnetic clutch, which provides automated control over feed operations with high precision.

- Includes an electronic speed variator, allowing for continuous adjustment of spindle speeds without needing to stop the machine, offering greater flexibility in machining various materials.

- Features a digital RPM counter, providing real-time spindle speed monitoring for improved process control.

- THV Models:

- Utilizes a mechanical clutch for automatic feed, providing reliable performance for repetitive tasks but without the electronic control features of the THI models.

- Comes with a mechanical speed variator, offering a more hands-on, manual adjustment of spindle speeds, making it suitable for operators looking for a more traditional, robust solution.

Both models share the core benefits of the TH Series, including a rotating and tilting table, high-quality transmission, and a built-in coolant system. However, THI models are more focused on automation and fine control, while THV models emphasize manual control and mechanical reliability.

| Specification / Model: | THI.40 | THI.50 |

|---|---|---|

| Drilling (mm): | 40 | 50 |

| Tapping (mm): | M36 | M42 |

| Transmission: | BELT/GEAR | BELT/GEAR |

| Speed Range (3) (rpm) | 60-200 / 200-600 / 600-1500 | 60-200 / 200-600 / 600-1500 |

| Speed variator type: | Mechanical | Mechanical |

| Feed/Clutch: | Automatic | Automatic |

| Clutch: | Electro-Magnetic | Electro-Magnetic |

| Feeds: | 4 | 4 |

| Motor (hp): | 4 | 4 |

| Taper: | MT4 | MT4 |

| Stroke (mm): | 200 | 200 |

| Spindle to Column (mm): | 360 | 360 |

| Spindle to Table (mm): | 1260 | 1260 |

| Spindle to Base (mm): | 55 / 850 | 55 / 850 |

| Column (Ø mm): | 175 | 175 |

| Table with T-Slots (mm): | 550 x 550 | 550 x 550 |

| Base with T-Slots (mm): | 950 x 550 | 950 x 550 |

| CE Certified: | Yes | Yes |

| Weight Net/Gross (kg): | 660 / 750 | 660 / 750 |

| Packaging dimensions and volume: | 2200 x 700 x 1200 | 2200 x 700 x 1200 |

| Specification / Model: | THV.40 | THV.50 |

|---|---|---|

| Drilling (mm): | 40 | 50 |

| Tapping (mm): | M36 | M42 |

| Transmission: | BELT/GEAR | BELT/GEAR |

| Speed Range (3) (rpm) | 60 to 200 / 200 to 600 / 600 to 1500 | 30 to 300 / 90 to 900 / 190 to 1900 |

| Speed variator type: | Electronic | Electronic |

| Feed/Clutch: | Automatic | Automatic |

| Clutch: | Electro-Magnetic | Electro-Magnetic |

| Feeds: | 4 | 4 |

| Motor (hp): | 4 | 4 |

| Taper: | MT4 | MT4 |

| Stroke (mm): | 200 | 200 |

| Spindle to Column (mm): | 360 | 360 |

| Spindle to Table (mm): | 1260 | 1260 |

| Spindle to Base (mm): | 55 / 850 | 55 / 850 |

| Column (Ø mm): | 175 | 175 |

| Table with T-Slots (mm): | 550 x 550 | 550 x 550 |

| Base with T-Slots (mm): | 950 x 550 | 950 x 550 |

| CE Certified: | Yes | Yes |

| Weight Net/Gross (kg): | 660 / 750 | 760 / 850 |

| Packaging Dimensions (mm): | 2200 x 700 x 1200 | 2200 x 700 x 1200 |

Features

- Automatic Feed (Mechanical or Electromagnetic Clutch)

- Transmission: Belt/Gear Combination

- Rotating and Tilting Table

- Fixed Headstock

- Machine Base with Coolant Tank and Pump

- Electronic Speed Variator in THI models

- Mechanical Speed Variator in THV models

- Depth Scale with Adjustable Depth Stop

- Worklight Included

- Emergency Stop Push Button

- Gearbox Lubrication by Automatic Pump

- Spindle Reversing Switch

- Drill Guard with Micro-Switch

- CE Certified

Optional Extras

- Depth Digital Reader

- Reduced Feeds (50% of Standard Range)

- Rotating and Tilting Table

- Column Supplement (200 mm)

- Pneumatic Counterbalance for Rapid Approach and Retract

- Speed Digital Reader (for models with Variator)

Erlo: Tradition and Innovation in Drilling and Tapping Machines

Erlo is a leading manufacturer of drilling and tapping machines, with over 50 years of experience in the industry. ERLO is known for reliable and durable machines, which are made with high-quality materials and components. ERLO’s machines are also easy to use and maintain, making them a good choice for machinists and metal fabricators of all levels of experience.

In addition to the standard range of drilling and tapping machines, also offered are customized solutions for specific applications are designed with a deep understanding of the custoer’s needs and the machine designs meet those needs perfectly.

It is the belief that tradition and innovation go hand-in-hand and ERLO has a committment to providing their customers with the latest technology and also value the traditional values of craftsmanship and quality.

If you are looking for a reliable and innovative drilling and tapping machine, Erlo is the perfect choice for you. Contact us today to learn more about our products and services.

ERLO products are proudly sold by The Workshop Press Company UK based in Kenilworth, Warwickshire.