- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

50 Ton Compact Four Column Press • PPSFC Series • RHTC

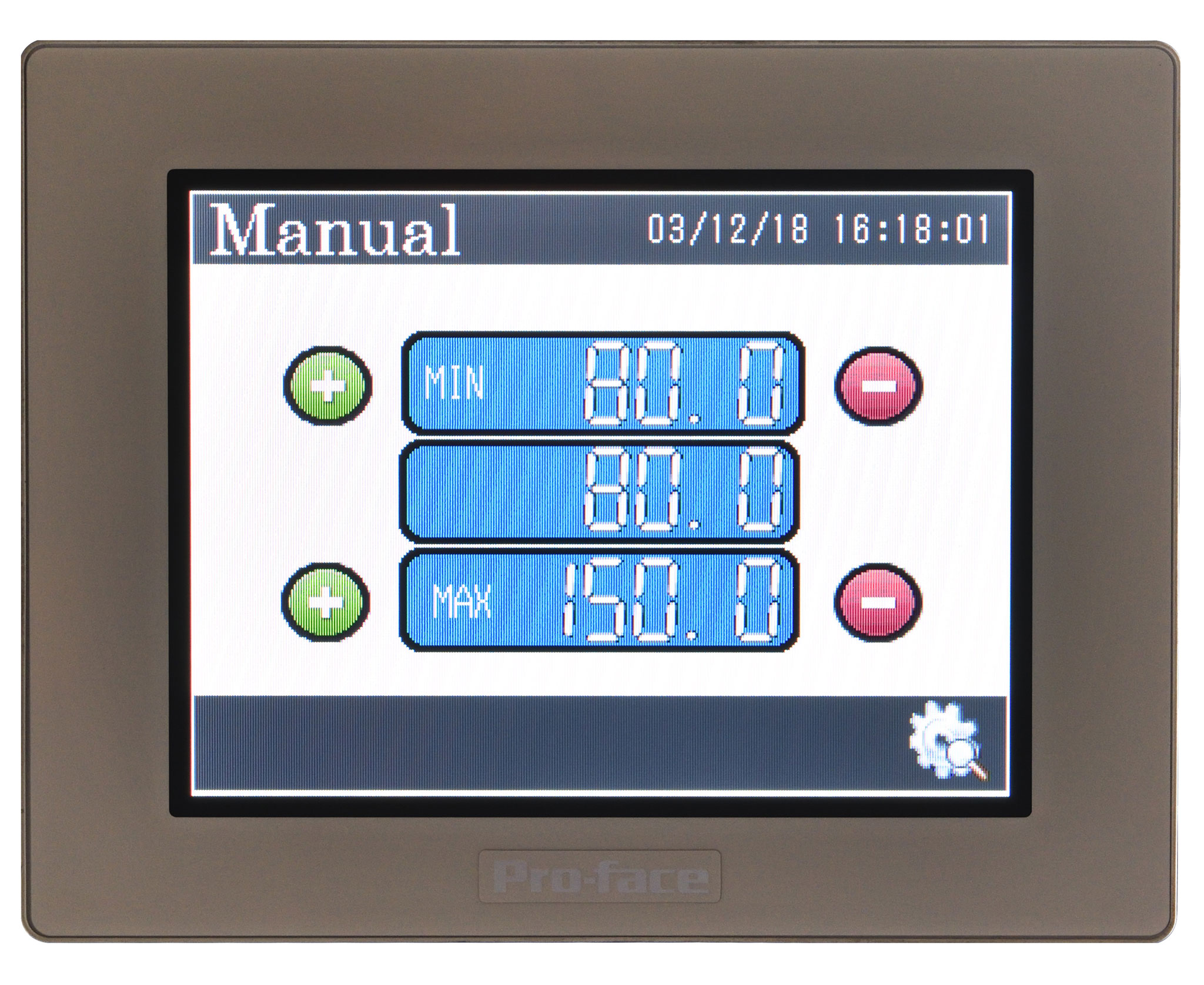

Product Code: PPSFC50The 50 Ton Four Column Press - PPSFC-50 is a compact yet versatile hydraulic press designed for cutting, embossing, stamping, and other metalworking tasks. Manufactured in Europe, this press delivers exceptional accuracy with its electronic NC controller, enabling precise adjustments of the piston stroke to within 0.1 mm.

Equipped with manual and semi-automatic operation modes, the PPSFC-50 ensures flexibility and ease of use. Its robust table features T-grooves and a central hole, allowing various tooling options. With adjustable pressing force and speed, this hydraulic press is a reliable solution for a wide range of metalworking applications.

Contact us today to learn more about the PPSFC-50 or request a customized quote for a press tailored to your specific requirements!

Please contact for prices

- Description

- Additional Info

The PPSFC-50 is a high-quality hydraulic press designed for smaller-scale yet precise applications.

Key Benefits:

- NC Controller: Regulate the piston stroke with 0.1 mm accuracy.

- Flexibility: Operate in manual or semi-automatic mode for convenience.

- Durable Construction: The table is equipped with T-grooves and a central hole to accommodate various tooling.

- Adjustable Settings: Fine-tune pressing force and speed with hydraulic adjustment valves.

- European Quality: Built with premium materials, ensuring reliability and long-term performance.

This press can also be customized with larger tables, increased vertical light, higher speeds, or light guards upon request.

Technical Specifications

- Pressure Force: 50 tons

- Motor Power: 5 kW

- Min. Working Speed: 2 mm/sec

- Max. Working Speed: 9.8 mm/sec

- Return Speed: 12.8 mm/sec

- Piston Stroke: 350 mm

- Vertical Light: 500 mm

- Table Size: 560 x 270 mm

- Total Width: 1150 mm

- Total Length: 750 mm

- Total Height: 2450 mm

- Weight: 2700 kg

Key Features

- NC control to set the piston stroke

- Selector for manual or semi-automatic operation

- Flow adjustment valve and pressure control valve

- Integrated pressure manometer

- Different tooling can be installed onto the table

Optional Accessories

- A frontal sliding lower table

- Adaptations to robotics

- Hydraulic connections for peripheral systems

- Higher speeds by prefilling valves and auxiliary cylinders

- Hydraulic cushion or ejector

- Cooling equipment for the hydraulic group by an air-oil cooling system

The PPSFC-50 is a compact 50-ton hydraulic press for cutting, embossing, and stamping. European-made, precise, and versatile.