- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

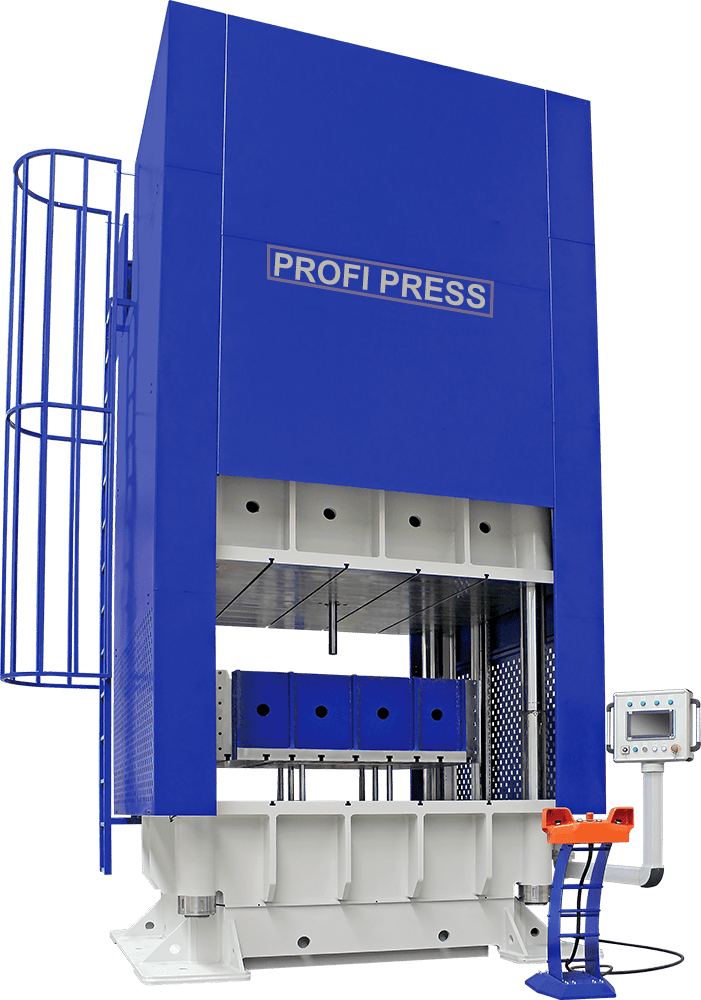

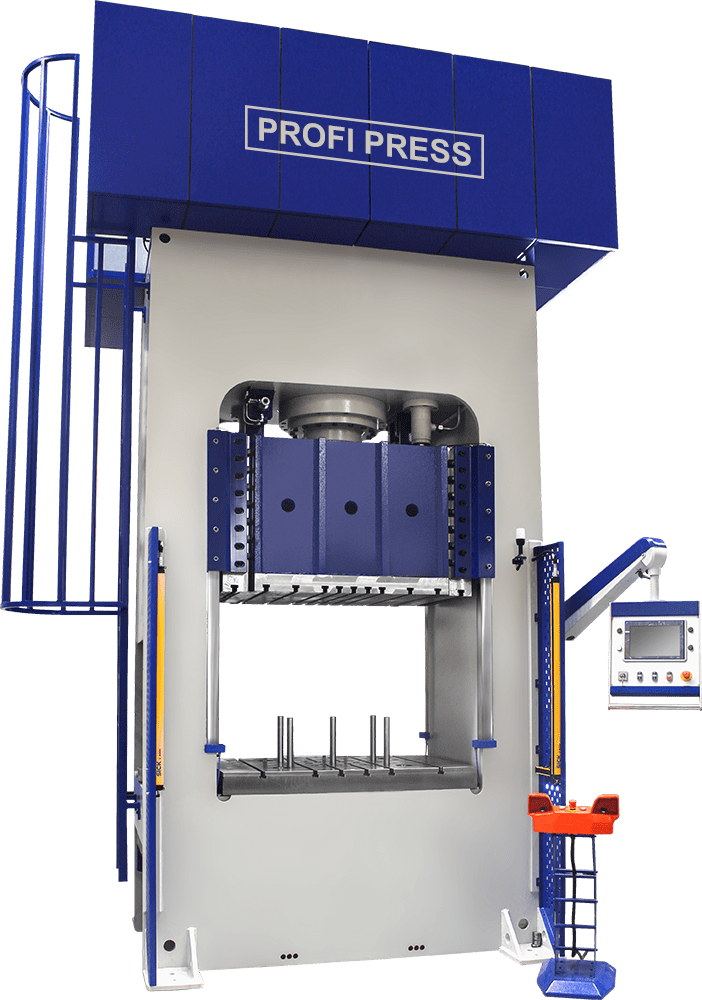

HDDT-600 • 600 Ton • Deep Drawing Press

Product Code: HDDT-600This 600 ton double action press with high speeds has a control panel featuring a touch screen. The control system permits programming the power, the cylinder stroke, and pressure time. And the machine operator operates this hydraulic press by means of two-hands push buttons.

Hydraulic Deep-Drawing Presses come in capacities from 400 tons up to 3000 tons. They are designed to carry out deep-drawing tasks in medium and high volumes either using one-off blanks or while being incorporated into automated production lines. The upper slide table and bottom bolster table come standard with DIN-650 T-grooves to allow for the easy mounting of moulds and tools, but customer T-Slot configurations are also available upon request. The HDDT Series come equipped with a hydraulic ram cylinder and a hydraulic cushion and the hydraulic power pack comes with an air-oil cooling system. The HDDT Series Deep Drawing Presses are high-speed controlled by a top-quality touch screen control panel which permits programming the tonnage, cylinder stroke, and pressure dwell time. The pressing cycle on all HDDT deep draw presses is initiated by the machine operator by means of two-hands push buttons, and safety is guaranteed by photo-electrical sensors situated at the front of the press, but alternative bespoke controls are available. All machines are delivered according to the latest CE standards with guaranteed quality.

The HDDT Series Deep Drawing Presses feature a rich assortment of features, and one special feature is the double-action cylinder and large tables with DIN-650 T-Slot grooves. Deep Draw Pressing Cycles are at high speeds of 100 mm per second with a return speed of 140 mm per second, allowing for large-scale and long-run production in an efficient time frame. The HDDT Series Hydraulic Presses come with hydraulic cushions and can be customised to suit special requirements, such as a larger stroke.

Hydraulic Deep-Drawing Presses come in capacities from 400 tons up to 3000 tons and are designed to carry out deep-drawing tasks in medium and high volumes either using one-off blanks or while being incorporated into automated production lines. The upper slide table and bottom bolster table come standard with DIN-650 T-grooves to allow for the easy mounting of molds and tools, but customer T-Slot configurations are also available upon request. The HDDT Series come equipped with a hydraulic ram cylinder and a hydraulic cushion and the hydraulic power pack comes with an air-oil cooling system. The HDDT Series Deep Drawing Presses are high-speed controlled by a top-quality touch screen control panel which permits programming the tonnage, cylinder stroke, and pressure dwell time. The pressing cycle on all HDDT deep draw presses is initiated by the machine operator by means of two-hand push buttons, and safety is guaranteed by photo-electrical sensors situated at the front of the press, but alternative bespoke controls are available. All machines are delivered according to the latest CE standards with guaranteed quality.

The HDDT Series Deep Drawing Presses feature a rich assortment of features and one special feature is the double-action cylinder along with large tables with DIN-650 T-Slot grooves. Deep Draw Pressing Cycles are at high speeds of 100 mm per second with the return speed at 140 mm per second allowing for large-scale and long-run production in an efficient time frame. The HDDT Series Hydraulic Presses come with hydraulic cushions and can be customised to suit special requirements, such as a larger stroke.

Please contact for prices

- Description

- Additional Info

Technical specifications

- Force [tn]: 600

- Motor power [kw]: 37

- Working speed [mm/sec]: 15

- Approaching speed [mm/sec]: 100

- Return speed [mm/sec]: 110

- Piston stroke [mm]: 1000

- Table size [mm]: 1500 x 1700

- Max. day light [mm]: 1000

- Hydraulic cushion [tn]: 250

- Hydraulic cushion stroke [mm]: 300

- Total length [mm]: 3000

- Total width (frontal) [mm]: 2800

- Overall height [mm]: 5500

- Weight [kg]: 33000

Features of this 600 tons hydraulic press

- Chrome plated cylinder and a steel welded frame

- T-slotted tables

- Main cylinder and hydraulic cushion

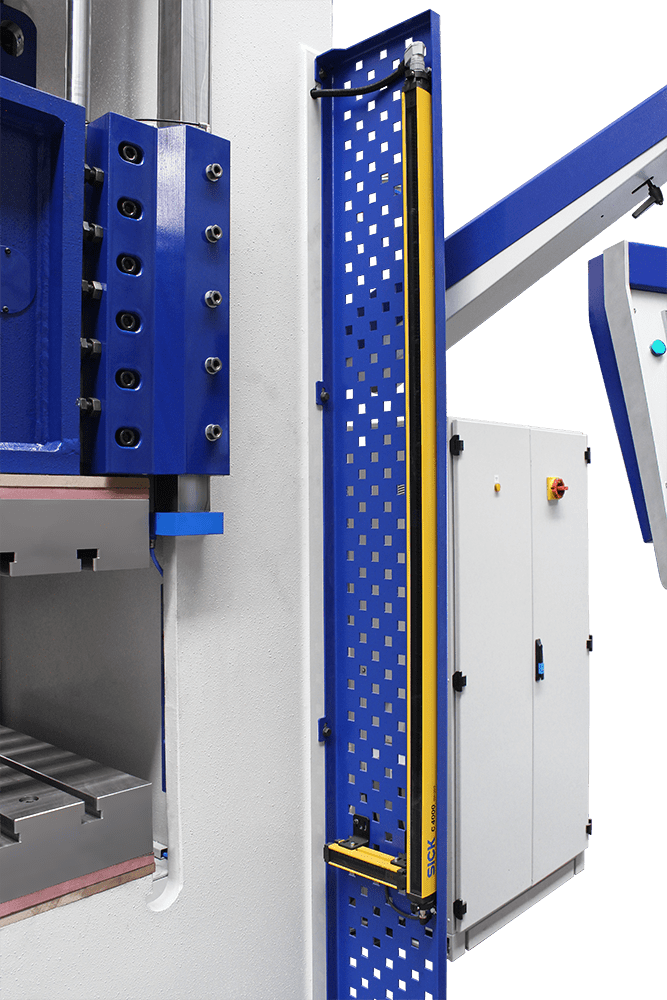

- Safety light guards at the frontal working area

- HMI Touch Screen control panel to program pressure, cylinder stroke & pressure time

- Lubrication system

- Oil pressure gauge

- Operation by means of a two-hands button control

Optional accessories

- Geometry adapted to your requirements (for example larger tables or a larger piston stroke)

- Hydraulic ejector cylinder in upper table

- Variable speeds

- Tool loading device

Available up to 3000 tons capacity and also available without hydraulic cushion, ask us for more information.

The Standard Technical Features and Specifications vary from press to press, and the chosen press should be appropriate to encompass all your applications. Some standard technical features of the HDDT Series Presses include standard tonnages from 100 to 3000 tons, programmable speeds, and a standard working speed of 10 mm per second. Piston stroke is a consideration with the standard range offering a piston stroke of 1000 mm and Vertical Daylight of 1000 mm. Large table sizes range from 1200 x 1400 mm to 1500 x 1700 mm. The presses are outfitted with a hydraulic cushion with 150 tons and a stroke of 300 mm. The main Press Cylinders are Chrome Plated, and the Frame is a steel welded frame. The top slide and bottom bolster tables come with standard DIN-650 T-slots. The HDDT Series Deep Draw Presses come standard with Safety Light Guards at the front of the press and the primary control is an HMI Touch Screen control panel that allows for programming pressure, cylinder stroke & pressure dwell time.

The HDDT Series as a standard offering, is feature-rich but optional accessories and bespoke features are available. Some examples are the adjusted physical size of the press, larger tables, smaller tables, larger piston stroke, hydraulic ejector cylinder in the upper table, variable speeds, and tool loading devices.

CE Certificate

This press comes with a standard 2-Year Warranty and a CE Certificate as standard.

All Profi Presses by RHTC are customizable, integrative, and have custom tools available.

Please contact Workshoppress today with any questions by telephone at +44 (0) 800 999 1090, or by email at info@workshoppress.co.uk.