Horizontal Press Brake 150 Ton Standard Control

Product Code: HPB-150The HPB-150 Horizontal Hydraulic Press Machine 150 Ton model with standard controls is extremely versatile and is ideal for precision bending, straightening, punching, and shearing making it possible to produce a vast assortment of different parts such as braces, hooks, rings, brackets, clips from heavy-duty metal.

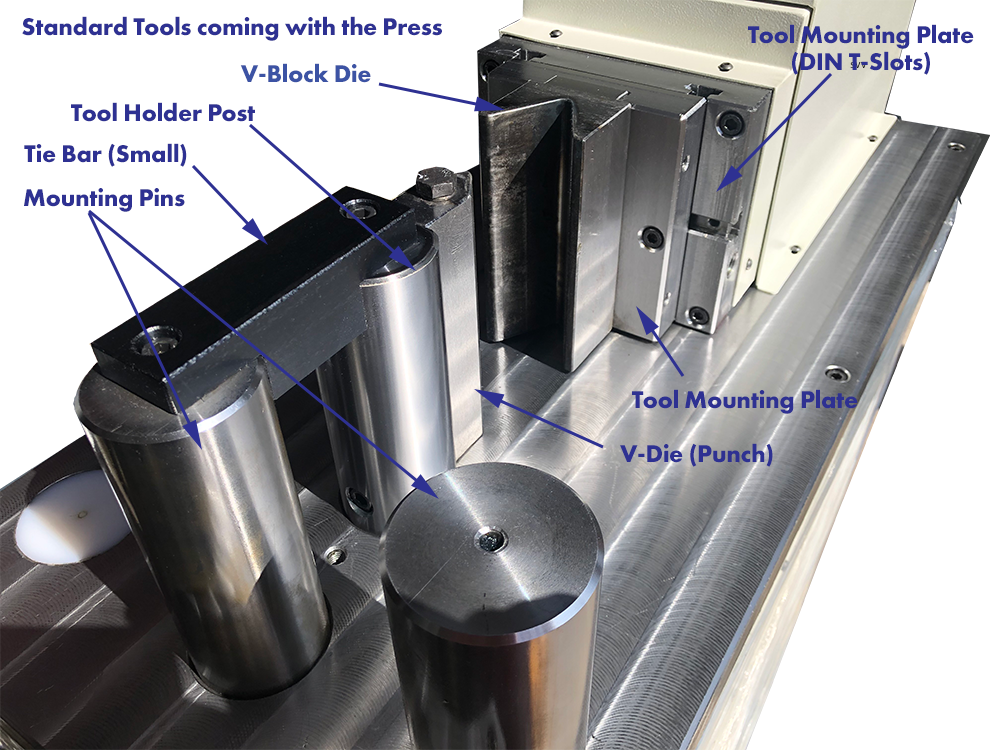

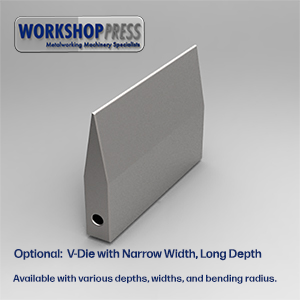

The different tools available for Horizontal press brakes are countless but some of the most common tools are for metal folding, bending, punching, crimping, cutting and other tools for bending tube, pipe and metal profiles are also available. Some optional tools are portrayed underneath the machine.

With years of experience in the manufacturing industry, our staff can also assist you in designing custom tools to address your applications.

These horizontal press machines are available with capacities from 10 up to 150 tons and with and are manufactured according to the most current CE regulations.

Please contact for prices

- Description

- Additional Info

Technical Specifications

- Max Pressure [tons]:

150 Tons - Oil Tank Capacity [litres]:

200l - Tooling Working Height [mm]:

600 - Max Pipe Bending [mm]:

On request - Stroke [mm]:

500 - Support Pin Diameter [mm]:

150 - Working Speed [mm/sec]:

10 - Return Speed [mm/sec]:

10 - Motor Power [kW]:

17.5 - Net Weight [kg]:

7500 - Length of the Machine [mm]:

1975 - Width of the Machine [mm]:

950 - Height of the Machine [mm]:

1630 - Size of Packing (LxWxH) [mm]:

2050 x 1100 x 1800

Features

- NC Controller Holds 99 Programs, 15 Steps Each

- Adjustable piston stroke and return by step

- Manual and Automatic Program Modes

- Flow adjustment valve for pressure

- Pressure manometer

- Back gauge

- V-Die (5 mm radius)

- V-Die Receptor (5 mm radius, 65 mm opening)

- Mounting Pins (2x)

- Pin for Tool Holding (1x)

- Modes: Manual and Automatic

Optional Accessories

- Tool Set for Bending Tubes

- Tool Set for Bending Flat Bar the Hard Way

- Tool Set for Straightening Beams and Sections

- Tool for Bending Sheet Metal into a Specific Shape

- Punching Tools

- Shearing Tools

Standard Tooling

- 2 pcs Back Support Pin

- 1 pc Tool Holder Pin

- 1 Adapter

Horizontal Press Brake

Bending flat bars is easy work with on horizontal press and you can bend components that are completely closed that are not possible to achieve on traditional press brakes. Bending tubes on a horizontal press brake is also possible and the press operator can achieve a wide variety of different bend angles. The flexibility horizontal press brakes, no matter with a standard control or NC Controller allows for the easy production of tables, chairs, pool ladders, roll cages, cow catchers, bollards, fitness machines, street furniture, boxes, pans, playground equipment, and many other products. Press Brakes that are horizontal allow an operator to simply Straighten and bend large profiles to conform to certain geometries and can assist in prototyping process the prove complicated with other standard presses. Curves and bends are a cinch as well as is straightening faulty profiles. A shearing attachment enables the cutting of flat bars or sheets. These press machines expedite punching, boring, drilling processes and make perforating material for fences, doors, windows, and other parts an easy and efficient process. Also referred to as forming presses an operator achieves maximum efficiency when manufacturing clamps, eye bolts, flange, pipe holders, and other fasteners for pipes. With the correct toolset tube flaring and expanding is also made easy for assembly and subsequent welding to procedures on exhaust pipes, water pump lines, stacking metal furniture, railings, roll cages, and many others. Reducing pipe ends is also possible and it permits neatly joining different pipes to make berths, chairs, piping systems, garden gazebos, tents, and greenhouses. Bending and folding solid rods enables a manufacturer to produce a vast variety of hooks, chains, links, and balusters from a square, rectangle, and round bars. Cold forging can also be accomplished on tubes when manufacturing railings, fences, gates, doors, railings, and hinges. All of these are common applications on a WorkshpPress.co.uk hydraulic press. Horizontal Bending Presses from WorkshopPress.co.uk increase efficiency and make you money.

CE Certificate

This press comes with a standard 2-Year Warranty and a CE Certificate as standard.

All Profi Presses by RHTC are customisable, integrative, and have custom tools available.