Horizontal Press Brake Applications

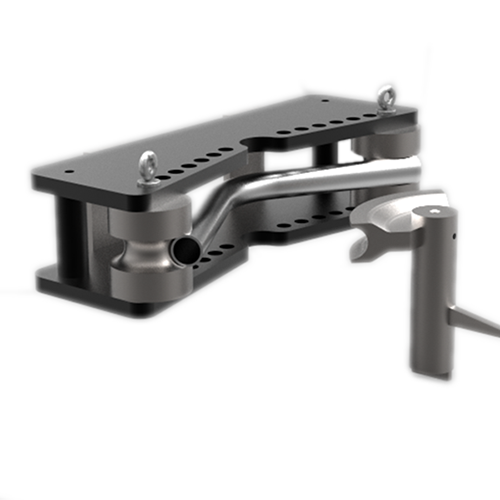

Product Code: Bend-Samples-HPB-MachinesHorizontal press brakes are highly versatile machines used to bend various profiles and shapes with precision and accuracy. They are capable of shaping flat sheets, plates, angles, channels, tubes, pipes, bars, and custom profiles, making them essential in a wide range of metal fabrication applications. By utilizing custom dies and punches tailored to the specific profile being bent, these machines ensure proper support and prevent distortion. With advanced precision control through NC and CNC systems, horizontal press brakes can achieve complex bending sequences, including multiple-radius bends and intricate curves. They are also equipped with support systems to maintain alignment, particularly for long or complex workpieces, ensuring consistency and repeatable accuracy across production runs. These features make horizontal press brakes ideal for industries requiring high precision and reliability, such as structural engineering, aerospace, and automotive manufacturing.

Please contact for prices

- Description

- Additional Info

Metals that can be Bent by HPBs:

Steel Varieties:

Mild steel: For general fabrication.

Stainless steel: For corrosion-resistant applications.

High-strength, low-alloy steel: For structural components.

Tool steel: For durable tooling requirements.

Aluminum Alloys:

Series 3000, 5000, and 6000 aluminum: For a balance of strength and flexibility.

Copper and Copper Alloys:

Pure copper: For electrical components.

Bronze and brass: For decorative and functional parts.

Titanium:

Grade 2 and 5 titanium: For aerospace and medical applications.

Nickel Alloys:

Nickel alloys: For high-temperature and corrosion-resistant applications.

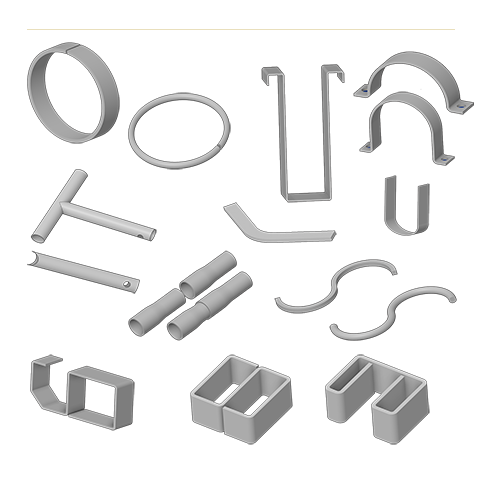

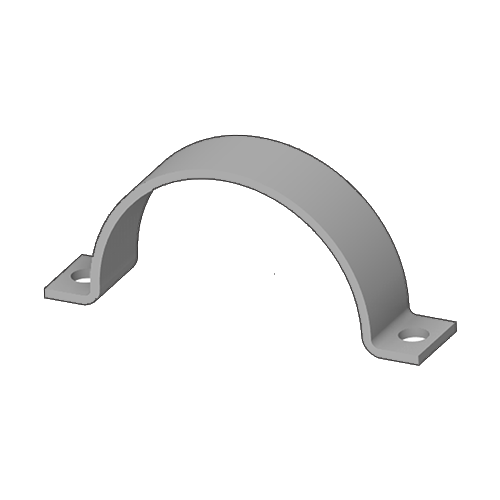

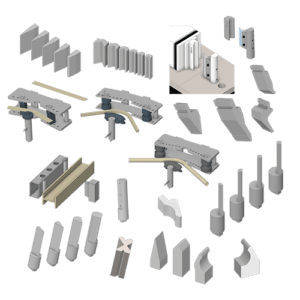

Profiles & Shapes Bendable by HPBs:

Flat Sheets and Plates:

Bending into forms such as pans, boxes, and brackets.

Angles and Channels:

Creating frame structures, supports, and enclosure frames.

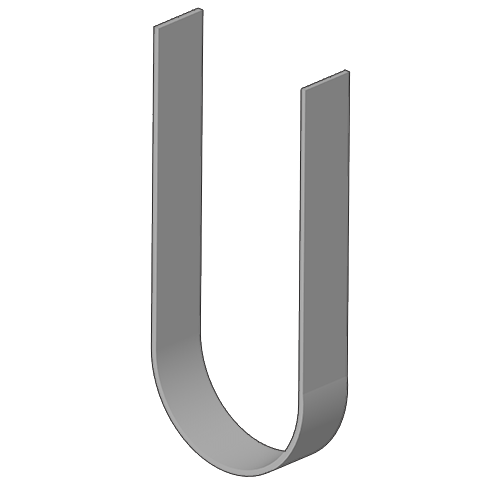

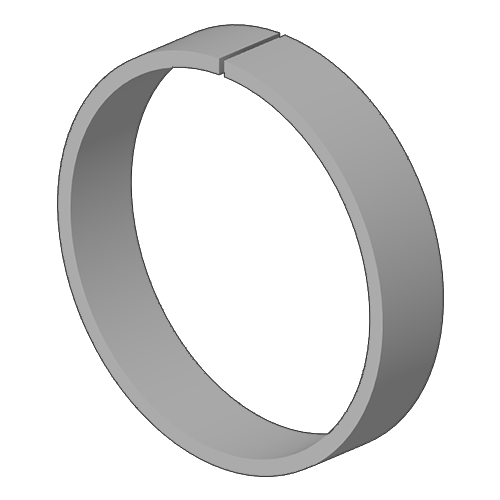

Tubes and Pipes:

Round: For fluid transport and structural applications.

Square and rectangular: For framework and architectural features.

Bars:

Flat bars: For supports and reinforcements.

Round bars: For rods and axles.

Square bars: For frames and machine parts.

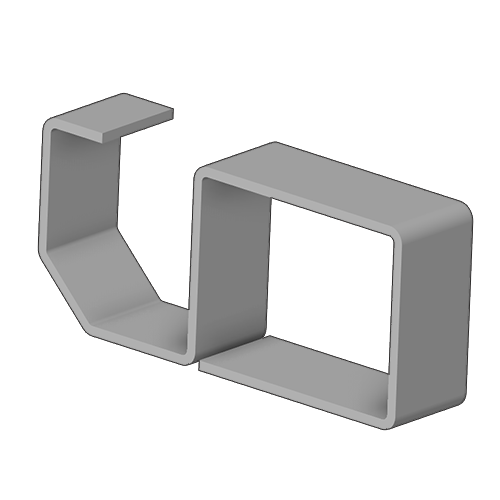

Custom Profiles:

Tailored to specific engineering designs, including complex geometric sections.

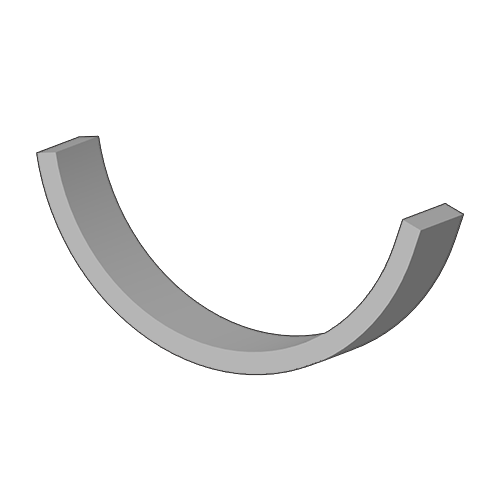

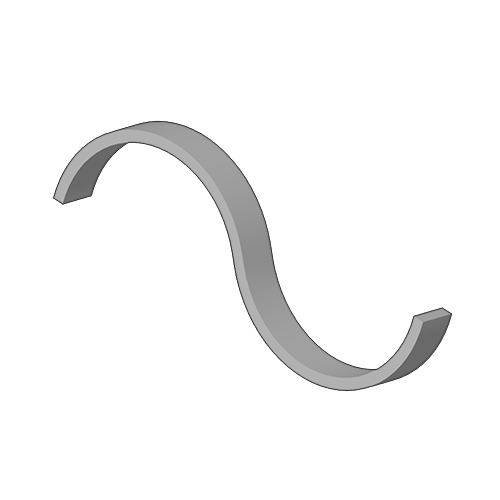

Complex Shapes:

Including serpentine bends, multiple-radius curves, and 3D bending for intricate designs and assemblies.

Bending Different Types of Metals:

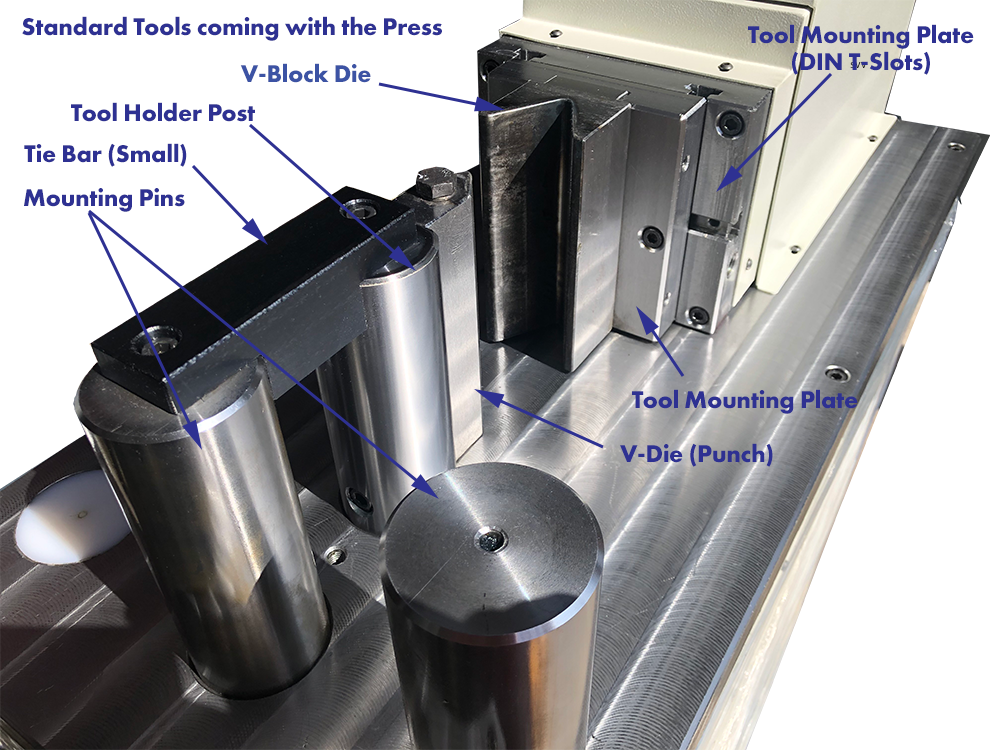

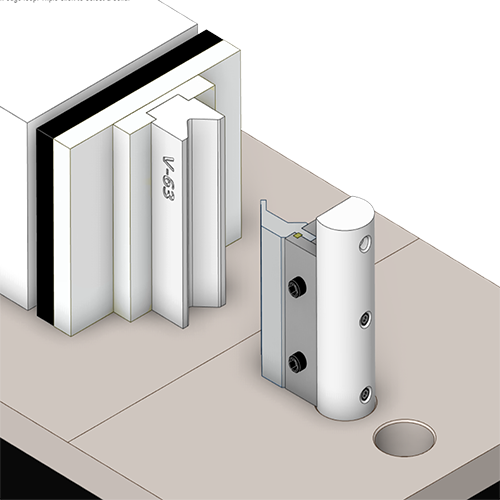

Process Explanation: Horizontal press brakes function through the application of force via a hydraulic or mechanical system, which pushes a punch (upper tool) into a die (lower tool) to bend the metal placed between them. The process for bending different types of metals involves several key steps and considerations:

Material Properties:

Each type of metal has unique properties such as ductility, tensile strength, and hardness. The press brake must be set with the appropriate force and speed to accommodate these properties. For instance, bending titanium or high-strength steel requires more force compared to aluminum, which is softer and more pliable.

Tooling Selection:

The choice of tooling is critical and depends on the metal type and desired bend. Harder metals might require tooling made from robust materials to withstand the forces without deforming.

Programming:

For Horizontal Presses with NC (Numerical Control) or CNC (Computer Numerical Control), the machine can be programmed with specifics about the metal type, thickness, and desired bend angle. Advanced controllers can automatically adjust parameters to compensate for factors like springback, which varies between different metals.

Bending Process:

The actual bending process involves the metal sheet or workpiece being placed on the die, with the punch then moving into the material to form the metal into the desired angle or shape. For metals with higher springback (like high-strength steel or certain aluminum alloys), the press brake should be programmed to over-bend slightly to achieve the correct final angle after the material springs back.

Shaping Various Profiles and Shapes:

Process Explanation: The versatility of horizontal press brakes extends to bending various profiles and shapes, from simple angles to complex curves.

This capability is achieved through:

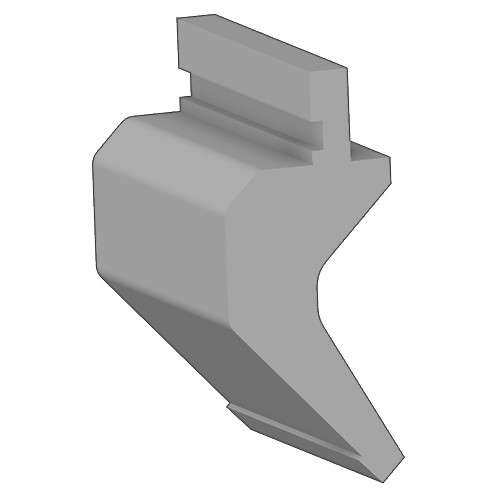

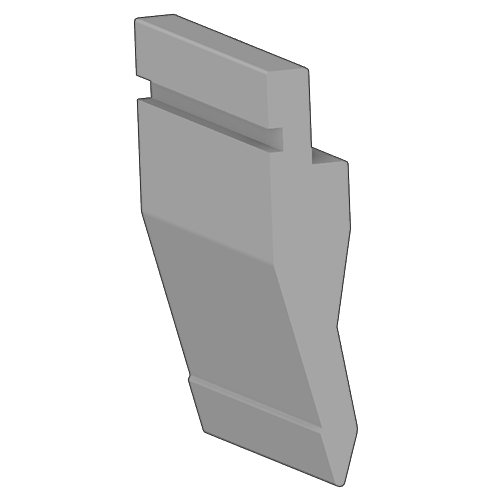

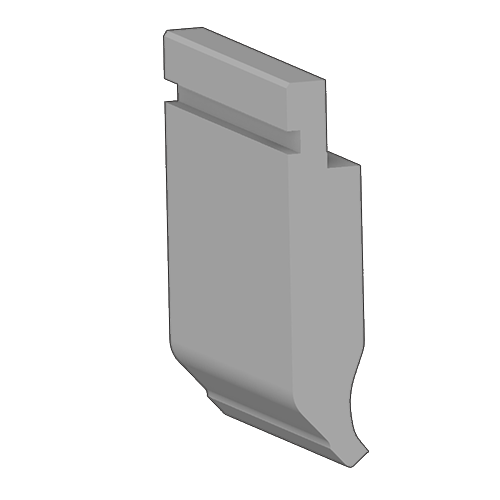

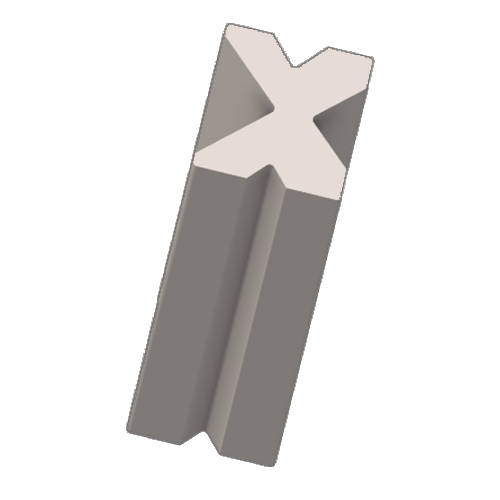

Custom Dies and Punches:

To handle different profiles (such as tubes, bars, or custom shapes), specialized dies and punches are used. These tools match the profile’s shape, ensuring that the metal is supported properly during the bending process to prevent distortion or collapse.

Precision Control:

For complex shapes or multiple-radius bends, precision control over the bending process is essential. This is where NC comes into play, allowing for the programming of intricate bending sequences with precise control over bending angles, depth, and force.

Support Systems:

For bending long or complex profiles, support systems may be used to prevent the workpiece from twisting or warping. These systems help in maintaining alignment and uniformity across the bend.

Repeatable Accuracy:

Especially important for series production of specific shapes or profiles, horizontal press brakes with advanced control systems can store and repeat bending programs. This ensures consistency across batches, crucial for parts that must fit together in assemblies.

In both cases, whether bending different types of metals or shaping various profiles and shapes, the expertise of the operator and the capabilities of the horizontal press brake play a crucial role. The ability to adjust settings, choose the right tooling, and accurately program the machine determines the quality of the finished product, showcasing the blend of technology and skill inherent in modern metal fabrication.