PPC-28 C-Frame Press • 28 Ton Profi Press

Product Code: PPC10010The Profi Press PPC-28 is a versatile hydraulic press designed for precision metalworking. Equipped with an NC controller, it allows digital adjustments of the piston stroke for sub-millimetre accuracy, ensuring consistency in stamping, punching, cutting, and riveting operations. Its robust structure, coupled with a built-in manometer for pressure monitoring, makes it a reliable solution for various industrial applications.

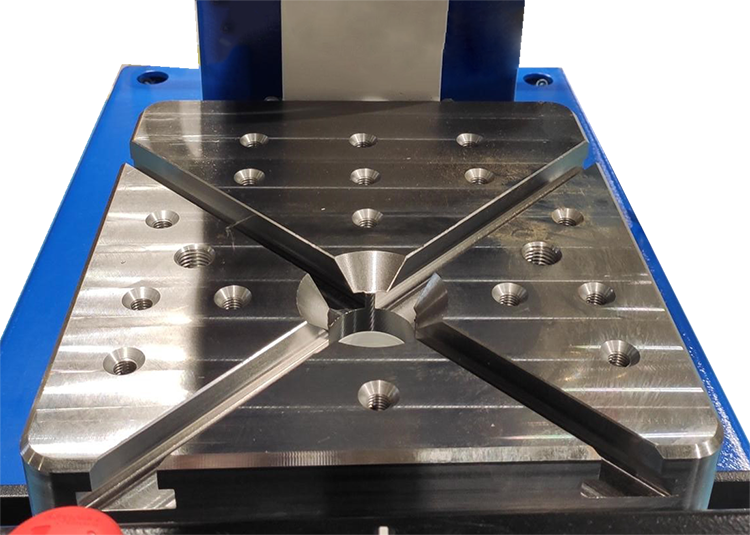

This C-Frame press offers both manual and semi-automatic modes, providing adaptability for different production settings. The lower table features T-grooves for secure tool placement, and the system includes foot pedal operation for ease of use. The press also comes with safety measures like emergency buttons and optional guarding accessories, all designed with CE Certification standards in mind.

Whether used in high-volume production or a more specialized workshop, the PPC-28 guarantees high precision, operational efficiency, and a long service life.

- Description

- Additional Info

The Profi Press PPC-28 C-Frame Press is a 28-ton capacity hydraulic press ideal for various cold metalworking applications such as stamping, punching, and notching. Manufactured in Europe and certified according to CE directives, this press is equipped with an NC controller for digital stroke control and features dual operational modes for maximum flexibility. With precise hydraulic adjustments, it is designed for industries requiring efficiency and accuracy.

Technical Specifications

- Pressing Force: 28 tons

- Max. Pressure: 200 bar

- Max. Working Speed: 9.8 mm/s

- Piston Stroke: 150 mm

- Vertical Daylight Max.: 280 mm

- Vertical Daylight Min.: 130 mm

- Min. Working Speed: 2 mm/sec

- Return Speed: 12.8 mm/sec

- Piston Diameter: 70 mm

- Piston Tool Hole: 40 mm

- Throat Depth: 225 mm

- Table Size: 325 x 300 mm

- Length: 902 mm

- Width: 700 mm

- Height: 1996 mm

- Weight (Net): 572 kg

Features

- 28-ton hydraulic pressing force

- Manual and Semi-Automatic modes

- NC-Controlled piston stroke for precise operation

- Safety systems with emergency buttons

- Adjustable hydraulic pressure and speed

- Built-in manometer for real-time pressure monitoring

- Foot pedal operation for hands-free control

- Robust European construction for long-lasting use

- Customizable for various metalworking tasks

- CE Certified for safety and compliance

- 2-year warranty included

Industries Using and Their Uses

- Automotive: Forming and punching of car body components

- Aerospace: Precision stamping for high-strength alloys

- Metal Fabrication: Sheet metal cutting and forming

- HVAC: Production of ductwork components

- Electrical: Punching holes in enclosures and panels

28-ton capacity Profi Press PPC-28 C-Frame hydraulic press with NC stroke control and dual operational modes, offering exceptional precision and durability for metalworking tasks.