- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

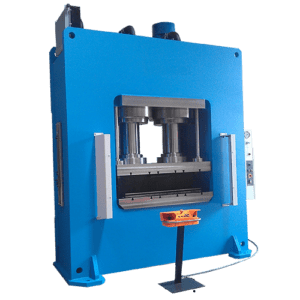

220 Ton Hydraulic Motorised Production Press

Product Code: 220T-ProductionThe 220 Ton Hydraulic Production Press offers powerful and versatile metal forming capabilities for a range of industrial tasks. Featuring an electro-welded frame made from high-strength S355JR steel, the press ensures structural integrity and long-lasting performance. The double-acting cylinder, paired with a two-speed motorized hydraulic group, provides precise control for complex forming operations.

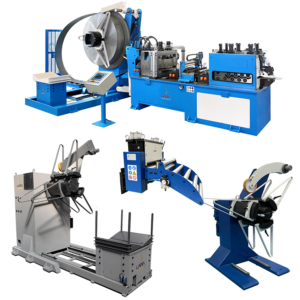

Equipped with a SIEMENS PLC and a 4” touchscreen, this press allows easy configuration of stroke, power, and dwell time, while the built-in safety features, such as type 4 PLe photoelectric barriers, ensure operator protection. With the capacity to store 99 production recipes, the press is ideal for repetitive and high-volume tasks. The machine integrates seamlessly into automated production lines or with coil feeding and straightening systems from Workshop Press Co UK, making it an adaptable solution for any production environment.

Please contact for prices

- Description

- Additional Info

The 220 Ton Motorised Hydraulic Production Press is engineered for high-capacity metal forming operations such as stamping, punching, and deep drawing. Its robust electro-welded frame, constructed from S355JR steel, provides the durability and precision required for demanding industrial applications. Operating at a maximum pressure of 320 BAR, this press ensures reliability and longevity in every production cycle. Easily integrated into production systems or coil feeding and straightening systems from Workshop Press Co UK, the press helps streamline workflows and increase operational efficiency.

Technical Specifications:

- Power: 220 Tons

- Motor Power: 11 kW

- Working Speed: 3.8 mm/s

- Approaching Speed: 17 mm/s

- Return Speed: 30 mm/s

- Max Pressure: 320 BAR

- Piston Stroke: 300 mm

- Upper Table Dimensions: 700 x 550 mm

- Lower Table Dimensions: 800 x 600 mm

- Max Vertical Daylight: 500 mm

- Frontal Light: 900 mm

- Working Height: 1,000 mm

- Total Front Dimension: 1,095 mm

- Total Lateral Dimension: 1,875 mm

- Total Height: 3,045 mm

- Guide Diameter: 60 mm

- Weight: 4,680 kg

Features & Uses:

- Two-speed motorized hydraulic group with automatic disconnection for fast speed.

- Electro-welded structure from S355JR steel for high durability and precision.

- Maintenance-free bimetallic anti-friction bushings in the guide system.

- Programmable SIEMENS PLC with 99 recipe storage capacity.

- Type 4 PLe safety photoelectric barriers for operational safety.

Industries & Uses:

- Automotive Industry: Stamping and forming of vehicle body panels and structural components.

- Heavy Machinery Manufacturing: Forming large components for construction and mining equipment.

- Defense Industry: Precision punching and deep drawing of armored parts.

- Metalworking Industry: Versatile forming for custom and large-scale metal projects.

- Shipbuilding Industry: Forming hull sections and other large steel components.

220 Ton Motorised Hydraulic Production Press ideal for high-capacity deep drawing, stamping, and punching. Easily integrates into production systems or coil feeding and straightening systems offered by Workshop Press Co UK.