Profi Punch 16 TON Automated

Product Code: PPP10010-AUTOElevate your metal fabrication capabilities with the Automated PP-16 Press with Material Feeder System. This advanced machine is engineered to meet the most rigorous production demands, offering an unmatched blend of versatility and efficiency. Built upon the solid framework of our standard PP-16 model, this automated version enhances your operational efficiency to new heights.

A standout feature of this machine is its integrated PF2 Material Feeder System, which enables smooth, one-axis movement. The feeder's software is expertly designed for effortless integration with a diverse range of machines, such as presses, saws, drills, and cutters. This adaptability makes it the go-to choice for various technological processes like cutting, bending, punching, and more. Moreover, the press offers the flexibility to operate either with the integrated feeding system for high-volume production or independently for specialized tasks.

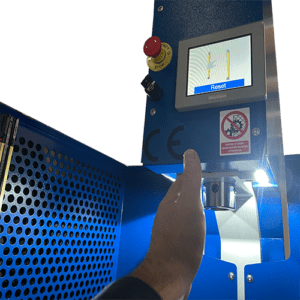

User control is simplified with an HMI panel located on the side wall of the press, facing the operator. This panel provides multiple operational modes, including manual and automatic, giving you the adaptability to meet different production requirements. Whether executing a single piston work cycle or managing a full production line, this machine delivers the features and reliability you demand.

The Automated PP-16 Press is more than just a machine; it's a comprehensive solution engineered to meet contemporary metal fabrication needs. Its customizable features can be tailored to your specific production requirements, making it an invaluable asset in any industrial environment.

Please contact for prices

- Description

- Additional Info

Technical Summary:

- Pressure Force:

With a formidable pressure force of 16 tons, this machine is built to handle even the most demanding tasks. - Motor Power:

Equipped with a 2.2 kW motor, it ensures efficient and reliable operation. - Working Speed:

Offers a minimum working speed of 2 mm/sec and a maximum working speed of 9.8 mm/sec, providing you with the flexibility to adjust based on your production needs. - Throat Depth:

Features a throat depth of 160 mm, allowing for greater versatility in handling various sizes of materials. - Vertical Daylight:

With a vertical daylight of 255 mm, it accommodates a wide range of material thicknesses. - Table Size:

The table measures 340 mm in length and 255 mm in width, providing ample workspace. - Return Speed:

Boasts a rapid return speed of 20 mm/sec, enhancing productivity. - Piston Stroke:

The piston has a stroke length of 70 mm, which is the same as the standard pitch of the PF2 feeder. - Power Requirement:

Operates on a 400V, 3-phase, 50 Hz power supply, ensuring compatibility with industrial electrical networks. - Dimensions:

The total dimensions are 800 mm in length, 450 mm in width, and 1430 mm in height. - Weight:

Weighing in at 350 kg, it’s a robust machine designed for industrial applications.

Added Features for Automated Press:

- Dual Functionality:

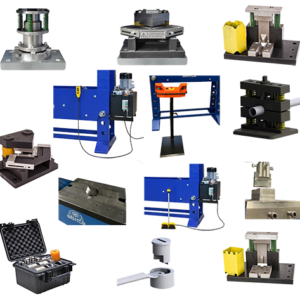

This automated press can serve both as a punching machine and a C-frame press, offering you unparalleled versatility in your operations. - Adjustable Piston Stroke:

The piston stroke can be adjusted up to 70 mm, allowing for greater flexibility in your production runs. - Manual/Automatic Mode:

Choose between manual and automatic modes to best suit your production needs. The automated features make it ideal for high-volume tasks. - Interchangeable Punch Tools:

The machine is compatible with a variety of punch tools, enhancing its utility. Here are some examples:- Corner wedge-shaped punch

- Pipe cutter for perpendicular pipe

- Slotted hole punch

- Corner rounding notcher

- Corner cutting notcher

- Hole puncher for pipes

- Sheet metal cutter

Additional Information:

Operation Modes: Choose between multiple operation modes, including PRESS and PRESS + FEEDER, via a 3-position selector switch, allowing for greater flexibility and efficiency in your operations.

Footpedal Switch: The footpedal switch is more than just a start button; it’s your gateway to various operational modes including AUTO, UP, and DOWN, offering you complete control over the machine’s functionality.

Warranty: Rest easy with our 12-month warranty that covers the feeder system, complete with terms and conditions that prioritize your peace of mind.

Customization: Your production requirements are unique, and so should be your machinery. The Automated PP-16 is fully customizable, allowing you to specify its capabilities to meet your exact needs, including options for autonomous operation.