Rubberpad Presses

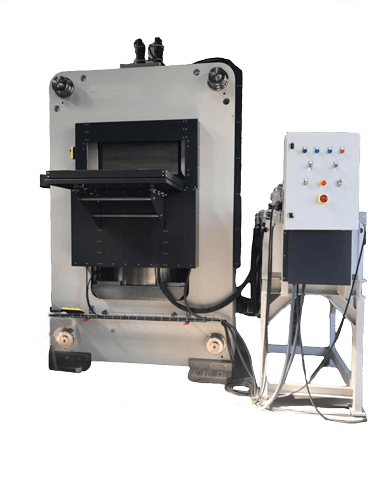

Product Code: RPP-2000Displayed is the RPP-2000; a 2000 Ton Rubber Pad Press with a large and rigid structure that can withstand the extensive stresses experienced during pressing operations. This version of the RPP-2000 is equipped with a tooling shuttle along with a mobile horizontal table that is moved by two double-acting hydraulic cylinders. The Rubber Pad forming press has an upward acting main cylinder putting into the classification of an Upstroke Hydraulic Press.

The top part of the press houses a block with a forming cavity and this is where the rubber blocks carry out the forming process. The displayed 2000 ton rubber press was manufactured by us with four ejector cylinders that are located at the top of the machine to facilitating the ejection the rubber blocks.

Please contact for prices

- Description

- Additional Info

This press is part of our Bespoke Press Program. We offer a wide variety of Hydraulic Presses in a variety of Press Categories and each press is customisable to suit. The RPP-2000 was designed together with our customer reassuring the customer that the Rubberpad Press would fulfill their requirements.

RPP-2000 Technical specifications

• Pressure force [tn]: 2000

• Motor power [kW]: 15 + 1,5

• Working speed [mm/sec]: 0,7 – 1,8

• Approaching speed [mm/sec]: 34

• Returning speed [mm/sec]: 50

• Maximum pressure [bar]: 340

• Piston stroke [mm]: 250

• Forming cavity [mm]: Ø 552

• Table- / working height [mm]: 2300 (there is a platform placed around the machine)

• Total length (lateral) [mm]: 3300

• Total width (frontal) [mm]: 2550

• Total height [mm]: 4200

• Weight [kg]: 44000

The Workshop Press Company UK supplies RHTC Rubberpad Forming Presses that are designed to your specific requirements.

Displayed is a 2000 Ton Rubberpad Forming Press that is 100% bespoke and suited to the customer’s production requirements. Together with our customer, we can fully design the press to suit the customer’s needs. If you are unsure about your requirements please contact us to discuss your specifications and requirements and our experienced staff will help you determine what the perfect press is for your needs.

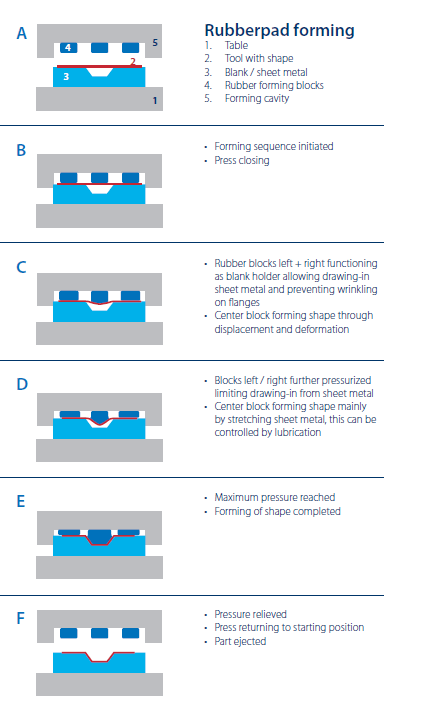

Rubber Pad Forming (RPF) also know by the technical term Elastoforming is a sheet metal forming process which employs a hydraulic press to exert force from one direction, typically towards down with the slide plate, onto a rubber polyurethane or elastomer block which pressures the sheet metal onto and over a forming tool, solid die, or a punch on the opposite side which is typically the bolster table of the press. RPF is considered by the press industry pundits as a deep drawing process which is a process which forms metal in two directions providing benefits in the areas of functionality, quality of finish, integration, weight reduction, and cleanability while reducing the prospect of defective parts. RPF can produce complex pressed parts that typically require multiple production processes such as cutting, bending, and forming of joints.

The RPF process is historically over 100 years old but many hydraulic press engineers attribute the development of the process to a gentleman by the name of Henry Guerin. Henry developed the process around the year 1930 to enable him to accurately, clearly, and efficiently manufacture structural aircraft components and is contemporarily a requisite process to have in house for a aerospace manufacturing company.

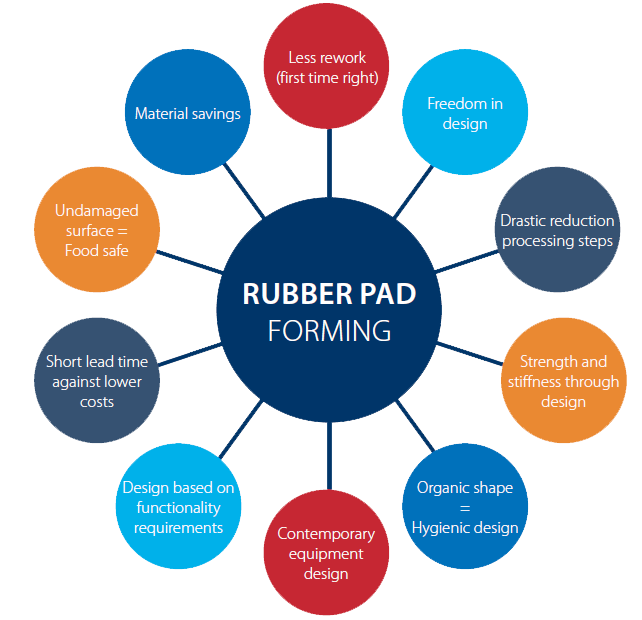

Rubber Pad Forming, or RPF, replace traditional press tool sets with flexible elastomer pads and minimizes up front tooling costs while at the same time simplifying forming processes. The Elastoforming process virtually removes all barriers of size and geometric configurations for pressing processes and after the component comes from the press required post pressing finishing operations are eliminated.

RPF is a responsive process that is suited for rapid prototyping and mid run production while eliminating the costly investment of production press tools. Elastoforming 3D tools can also be easily produced on 5 axis CNC machines or on 3D printers using either metal or industrial thermoplastics.

The material that can be used with the RPF process is limitless as long as the material is a ductile sheet of metal, but there is a limitation on the thickness of material that can be formed with the Elastoforming process. Some common materials used in the Rubber Pad Forming Process are 304 Stainless Steel typically up to around to 1.3 mm in thickness, 316 Stainless Steel up to 0.8 mm thick, Various Aluminium Alloys with some alloys being able to be just short of 5 mm thick, and Titanium Alloy up to around 1 mm thick.

The materials used for the rubber forming pad can vary but Polyurethane pads are typically used because of the outstanding durability Polyurethane offers and its inherent physical characteristics that withstand extensive forming pressures comparatively with other elastomers. But, some of the other alternative materials used in the RPF process are Natural Rubber, Silicone Rubber, and Styrene- Butadiene Rubber all of which have physical properties that resist abrasion.

Like any other manufacturing process, RPF or Elastoforming has many advantages but also has some limitations. The advantages that rubber press forming offers is that only one tool is required to perform the forming of the component and the tooling can be made at a relatively low cost and with a shorter lead time. Once the forming tool is manufactured it can be used with a wide variety of material thicknesses eliminating the need to change the forming tool when an alternative material thickness is required or desired. Other benefits include reduced forming radii and reduced material thinning during the forming process along with the elimination of die marks during the forming process, rendering the component ready-for-use once formed.

The limitations of Elastoforming / Rubber Pad Forming most also be taken into consideration when exploring the benefits this forming process can offer. The RPF process can delivery some serious stresses to the forming pad, so the intensity of the forming process and the corresponding pressures employer will limit the rubber pads lifetime. Other factors to consider are that the required forming pressure must be accurately calculated to produce quality parts, otherwise when insufficient forming pressure is used pressed components can be left unusable due to unformed corners or wrinkles. Another limitation is production speed, and when the RPF process is compared to a full production press setup, the RPF process is without a doubt slower. Another limitation is RPF pressed parts that are not designed with a suitable radius will experience problems. Sharp 90-degree corners cannot fully achieved with the use of a rubber pad. A generous radius allows the elastomer pad to flow appropriately during forming with sufficient distribution of pressure over the workpiece.

Elastoforming / RPF forming processes are suitable for a wide variety of situations, but not every situation. Hydraulic Press Rubber Pad Forming offers the manufacturer the ability to respond rapidly and, in a cost-effective manner when press components are needed within a short time frame, and often in a very cost-effective manner, and the RPF process typically loses its economic advantage when the quantity of required components start reaching the thousands, so it is very well suited for low to medium production volumes.

The aerospace industry widely employs the RPF process to manufacture pressed components because safety regulators recognise that traditional pressing process cause thinning, marring and stress concentrations all of which are alleviated by the RPF pr9ocess retaining the structural integrity of the material that is unquestionably required for airframe safety.

Outside of basic pressing and forming processes Elastoforming can utilize some Alternative Processes which include Metal Stamping, Warm Stamping, and Hydroforming. Metal Stamping is used where the material is ductile under normal conditions. Being that this process is similar to traditional pressing processes spring back management tactics are required to produce accurate pressed parts. Warm Stamping is another RPF process that is used with non-ferrous alloys that prove difficult to form at normal temperatures. Cooling and ageing of the metal is carried out under controlled processes in a controlled environment after forming is carried out to allow for the restoration of the metal microstructures that existed before the sheet is annealed for the forming process. Hydroforming is an advanced forming process used on sheets and tubes that uses a hydraulic system to delivery extensive and controlled pressure alternatively to that of a fixed amount of pressured being delivered from the top or bottom of the press. This process can produce geometries that are not attainable with standard pressing and stamping, primarily formations with undercuts or bulged shapes.

Setting up a press for RPF/Elastoforming requires a rubber pad and a containment structure that is fixed to the upper table, or slide table of the hydraulic press. On the bolster table, or bottom table of the press, a form block is used to contain the rubber pad. The process is initiated with the main piston of the press descending downwards forcing the elastomer pad to form around the form block forming the press piece. The retainer framework is fitted closely around the bolster enclosing the elastomer pad preventing lateral flow of the rubber pad when pressure is applied from the slide table. The overall forming process cause the rubber pad to flow somewhat like a fluid and exerting pressure equality on all workpiece surfaces and workspaces. RPF typically produces components with a profile that is 102 mm or less.

To ensure success during Elastoforming processes a technical review of a all the pertinent factors must be carried out by a qualified press application engineering, but there are a few common key factors that can be initially considered such as the geometric complexity of the component to be pressed and its overall size and the required production rates. Production Rates with RPF is slower in comparison to traditional pressing processes, but set-ups are quick, flexible and cost effective. The tools are typically not built to last for long runs or over long a period of time making the production quantity a pivotal factor when considering Elastoforming production runs. RPF is a production process that is relatively defect-free in comparison to other processes also retaining the surface quality of the pressed part eliminating the need for secondary finishing processes, thus making it more efficient. Some components can be produced form pre-painted and pre-finished metals.

Rubber Pad Forming is executed using a hydraulic press that is programmable either with simple controls or with a complex HMI that controls the repeatability of the stroke and of the forming tonnage whilst optimizing cycle times. The press does not have to be a dedicated “Rubber Pad Press” but, and with any machine, each machine has it constraints and limitations. Some other considerations are the vertical daylight of the press and then the stroke of the press. The vertical daylight must be adequate to facilitate the introduction of the raw material and removal of the pressed part. The stroke of the press must be adequate to allow for full compaction of the rubber pad. As previously stated, the physical process requirements for the RPF process can be rather complex and include such factors as the structure of the desired press, tool and die setup, employed materials, included radii, and the overall size and geometry of the press-part. Simple geometries make calculation to calculate the forming tonnage required quite easy with the use of engineering formulas.

This machine comes with a 2-year warranty and a CE certificate