- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

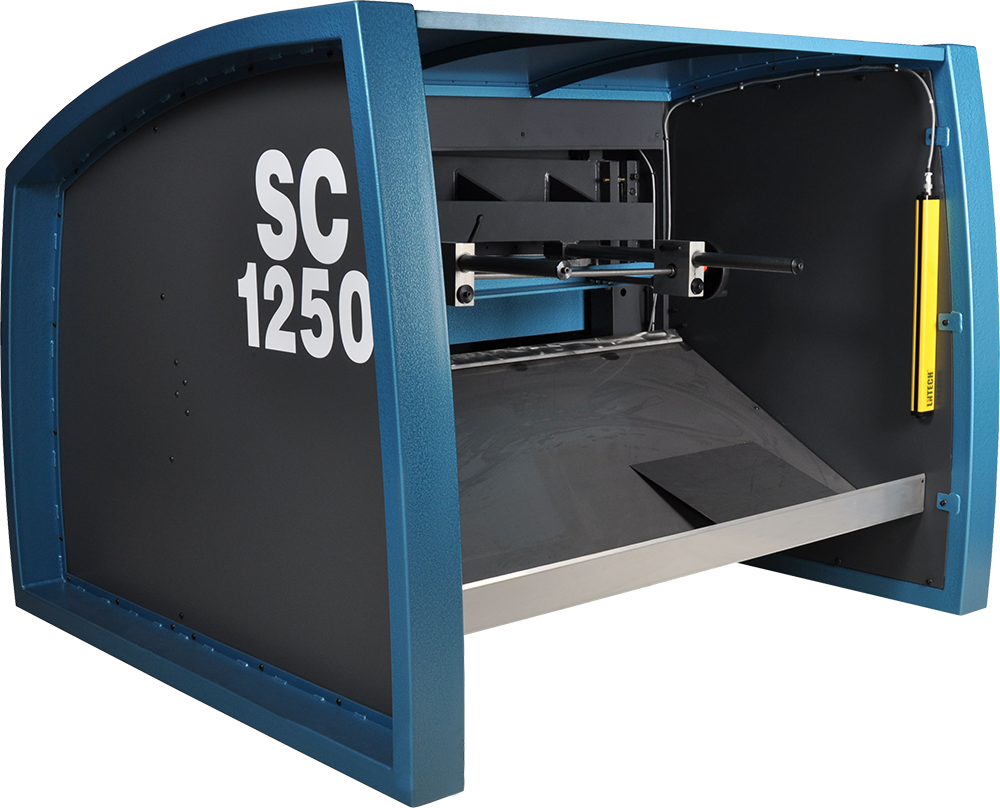

Motorised Guillotine Metal Shear • SCANTOOL 1250-40SM

Product Code: 00761255SCANTOOL proudly presents the Motorised Power Shears SCANTOOL 1250-40SM, equipped with a motorized back gauge and designed with a focus on modern aesthetics, quality, functionality, and ergonomics. These shears feature a new round shape with soft corners, offering a timeless and contemporary design.

Manufactured from the finest materials and components at our production facility in Poland, these shears are built to last. The innovative RTO patented feature directs cut pieces below 400 mm in length to the front, ensuring easy access for the operator. The ergonomically placed tray allows operators to remove cut pieces without bending, maintaining comfort and safety during operation. Additionally, the new knife gap adjustment system allows for easy adjustments from the front, simplifying maintenance and servicing.

Please contact for prices

- Description

- Additional Info

The SCANTOOL 1250-40SM Motorised Power Shears offer high precision and reliability in metal cutting operations. These shears are designed with an emphasis on quality, functionality, and operator ergonomics. The RTO system automatically directs cut pieces under 400 mm to the operator, enhancing efficiency and safety. The ergonomically placed tray allows operators to retrieve cut pieces easily without excessive bending. The shears are equipped with a new knife gap adjustment feature for straightforward servicing and maintenance.

Technical Specifications

- Capacity:

1275 x 4.0 mm - Sheet Thickness Steel:

4.0 mm - Working Length:

1250 mm - Motor:

4 kW - Cutting Angle:

2.15° - Cutting/Minute:

40 - Manual Back Gauge:

Yes - Length:

2100 mm - Width:

2000 mm - Height:

1500 mm - Net Weight:

1350 kg

Design

- Round shape with soft corners for a modern and timeless look.

Quality

- Manufactured in Poland with the highest quality materials and components.

Functionality

- RTO patented feature directs cut pieces below 400 mm to the front.

- Mirror for easy reading of the cutting line.

- Adjustable blade splitting from the front for easy servicing.

Ergonomics

- Ergonomically placed tray for cut-piece retrieval.

- Allows operators to keep gloves on and maintain comfort during operation.

Standard Equipment

- Patented RTO system:

Return to operator of items - Average counter

- Motorized plate stop

- Mirror:

For comfortable reading of the cutting line - Table extensions:

2 pcs., 600 mm each - Angle stop:

- Safety equipment:

With light beam - Double eccentric pull:

On the cutter bar - Self-lubricating slide guides:

- Low blade angle:

For a burr-free cut - Rubber coated plate holder:

- Single or multi-clip function:

- Removable foot pedal:

With emergency stop - Adjustable blade splitting:

From the front

Bullet Point List for Features and Uses

- Modern and ergonomic design

- High-quality construction

- RTO system for easy cut-piece retrieval

- Easy knife gap adjustment from the front

- Equipped with safety equipment and light beam

- Ideal for precision metal cutting

Industries Using the Machine and Their Uses

- Metal Fabrication: Accurate cutting of metal sheets and plates

- Manufacturing: Efficient production of metal parts

- Construction: Cutting metal components for building projects

- Automotive: Fabrication of automotive parts

Modern design motorised power shears with a motorized back gauge, featuring the innovative RTO system for easy cut-piece retrieval. High-quality materials and ergonomic design ensure top performance and operator comfort.