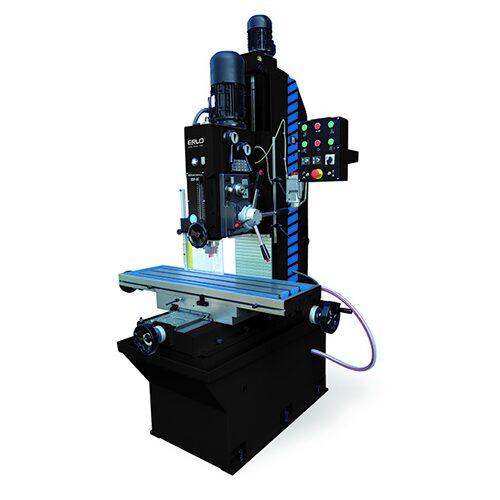

TF Series TF.35 Mill Drill from ERLO

Product Code: TF-SERIES-TF-35-ERLOThe ERLO TF Series Prismatic Column Drilling Milling Machines are engineered for precision and durability. These machines are equipped with automatic feed and an electromagnetic clutch, ensuring smooth and efficient drilling and tapping operations. With a drilling capacity of up to 35 mm in steel and a tapping capacity of up to M35, the TF Series is perfect for workshops requiring reliable and accurate drilling solutions. Standard features include motorized headstock displacement, prismatic column, manual greasing pump for guides, column, and table, depth adjustable end, and a frontal wheel for fine sensitive feed. The machines also come with coolant equipment, tool spanning system, lighting equipment, and compliance with CE norms for safety and quality.

Please contact for prices

- Description

- Additional Info

The TF Series stands out from other pillar drill presses in ERLO’s lineup due to its unique capability to function as both a drill and a milling machine. While traditional pillar drills in ERLO’s other series focus solely on drilling and tapping, the TF Series incorporates milling functions, making it more versatile for applications requiring both operations.

Here are the key differences:

- Prismatic Column Design: Unlike the cylindrical columns found in other ERLO series, the TF Series features a prismatic column that provides additional stability and rigidity, essential for milling operations where precise table movement and structural support are critical.

- Milling Capability: The TF Series is equipped with a cross table that allows precise longitudinal and transversal movements, making it capable of both drilling and milling tasks. This is a significant differentiator from other series focused primarily on drilling and tapping.

- Motorized Table Movement: While some other series may have manually adjustable tables, the TF Series offers motorized cross table displacement as an optional extra, which is beneficial for precise milling operations.

- Geared Transmission: Similar to other high-end ERLO drill presses, the TF Series uses a gear-driven transmission for reliable power delivery. However, its automatic feed system with an electromagnetic clutch is optimized for both drilling and milling, offering more control and efficiency during complex tasks.

- Multi-Functional Use: Unlike standard pillar drills, which are designed primarily for vertical drilling, the TF Series is suited for a range of machining tasks, such as milling, slotting, and drilling, making it highly versatile in a manufacturing environment.

In summary, the TF Series differs from other ERLO drill presses by offering advanced milling capabilities in addition to drilling, making it the ideal choice for applications requiring both precision drilling and milling within a single machine.

Specifications

- Drill capacity (mild steel): 35 mm

- Tapping capacity (mild steel): M35

- Milling capacity (mm): 55

- Transmission: Gear

- Number and range of speeds: (16) 94 – 2225 rpm

- Feed: Automatic

- Number and range of feeds: (3) 0.10-0.18-0.24

- Clutch: Electro-Magnetic

- Main motor power: 1.2 / 2 Hp

- Main motor speed (rpm): 750 / 1500 rpm

- Spindle cone: MT4

- Spindle stroke: 180 mm

- Distance spindle to column: 390 mm

- Distance spindle to table: Min 190 / Max 650 mm

- Dimensions of the cross table: 360 x 1220 mm

- Manual cross table stroke (standard): X=700 / Y=360

- Motorized cross table stroke (extra optional equipment): X=650 / Y=350

- Table with T-Slots: Yes

- Tilting table: 45º

- CE Certified: Yes

- Weight: net/gross kg: 910 / 1400 KG

- Packaging dimensions and volume: 2520 x 1680 x 711 mm / 7.1 m³

Features

- Automatic Feed with Electromagnetic Clutch

- Geared Transmission (Hardened and Ground Gears)

- Motorized Headstock Displacement

- Prismatic Column for Added Stability

- Manual Greasing Pump for Guides, Column, and Table

- Cross Table with T-Slots

- Adjustable Depth End with Fine Sensitive Feed Wheel

- Coolant Equipment and Lighting Included

- Tool Spanning System

- Emergency Push Button

- Turning Sense Selector

- Drill Guard with Micro-Switch

- CE Certified

High-performance prismatic column drilling milling machines with automatic feed, electromagnetic clutch, and geared drive. Perfect for precision drilling and tapping in metal fabrication.