- Bending, Straightening, Cambering

- Beam Cambering Presses

- Horizontal Press Brakes

- Portal Presses Manual Gantry

- Portal Presses Motorised Gantry

- Drawing and Stamping Presses

- Deep Drawing Presses

- Double Column Mechanical Presses

- Four Column Hydraulic Presses

- Production Hydraulic Presses

- Punching Machines

- Hydraulic

- Mechanical

- Metal Working

- Bandsaws for Industrial Metal Cutting

- Grinding & Sanding

- Centerless Grinders/Polishers

- Deburring Machines

- Guillotine Shears for Metal

- Lathes

- Mill Drills

- Notchers for Tube & Pipe

- Pillar Drills – Industrial

- Pillar Drills – Professional

- Profile Benders/Ring Rollers

- Slip and Plate Rolls

- Tube Benders & Tools

- Welding Positioners

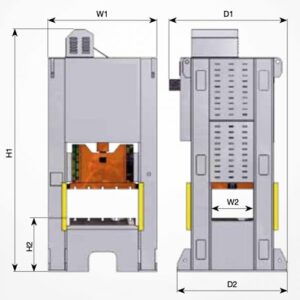

TWPCPMV Series Versatile Mechanical Presses • 100 to 400 tons • Variable Stroke • Digital Ram Adjustment

Product Code: TWPCPMV-SeriesThe PMV Series Mechanical Presses offer variable stroke capabilities, making them versatile and efficient for various industrial applications. These H-type one-point mechanical presses are built with robust construction and advanced features like pneumatic clutch and brake, dual safety valves, and automatic ram adjustment. The PMV Series is designed to meet the precision and adaptability needs of industries such as automotive, aerospace, and metal forming.

Please contact for prices

- Description

- Additional Info

PMV Series Mechanical Presses are designed for versatility and precision. These H-type one-point presses feature variable stroke capabilities, allowing for adaptability in different applications. Built with robust materials and advanced mechanisms, the PMV Series includes features such as pneumatic clutch and brake, dual safety valves, and automatic ram adjustment. These presses are suitable for industries requiring precise and adaptable metal forming solutions, including automotive, aerospace, and general manufacturing.

Technical Specifications:

- Press Capacity: 100 to 400 tons

- Stroke per Minute: 30 to 60 spm

- Stroke Adjustment: 150 to 200 mm

- Motor Power: 11 to 30 kW

- Table Dimensions: 900 x 1000 mm to 1100 x 1300 mm

Features and Uses:

- Variable stroke capabilities for versatility

- Pneumatic clutch and brake combination

- Dual safety valves for enhanced safety

- Automatic ram adjustment

- Digital ruler for precise ram adjusting

- Ideal for adaptable metal forming tasks

Standard Features

- Pneumatic Clutch & Brake Combination

- Dual Safety Valve

- Both Hands Control

- Foot Pedal Control

- Progressive Motorized Lubrication System

- Gears in Oil Tank

- Automatic Ram Adjustment

- Digital Ruler for Ram Adjusting

- Adjustable Stroke Movement

- Mechanical Rotary Cam Limit Switch (4 Array)

- Magnetic Cam Limit Switch

Standard Features (cont.):

- Programmable Control System (PLC)

- Touch-Operated Monitor

- Conformity of CE Machinery Directives

- Double Sided Photocell Safety Guard

- Hydraulic Overload Protector

- Safety Block

- Separated Piano Type Electric Panel

- Pneumatic Balancing Cylinders

- Rubber Anti-Vibration Pads

- 2 Year Warranty

Optional Features

- Inverter (speed variation)

- Pneumatic or hydraulic ejector

- Pneumatic or hydraulic die cushion

- Lower auxiliary table

- Strain gauge system

- NC digital display with memories

ADDITIONAL INFORMATION:

The double stanchion presses PM series are suitable for a wide variety of applications to industries such as automotive, aerospace, rail and many more related to metal forming. They are double reduction presses, with one or two connecting rods. They are made of S355JR steel, stabilized and machined at the end of the welding process to guarantee perfect parallelism and precision. Calculated and designed with finite element software. With all this, we always guarantee our high standards of precision and quality. The rod is built of high-strength forged steel and high-performance alloy bushings.

PNEUMATIC CLUTCH & BRAKE COMBINATION:

The clutch-brake is electropneumatic, equipped with a double safety body solenoid valve and crossflow. The pneumatic system includes a compensation tank, a regulator-lubricator filter, a control pressure switch, and a safety valve.

Industries Using the Machine and Their Uses:

- Automotive: Stamping, punching, forming

- Aerospace: Component manufacturing, deep drawing

- Rail: Structural part manufacturing, metal forming

MAINTENANCE and OPERATION:

To guarantee a perfect maintenance and operation, all our range is equipped with centralized automatic lubrication with a programmable progressive system.

Designed with a complex system of eccentric gears with opposite rotation that allows a double reduction in speed and long strokes. High energy is also obtained at very low nominal speeds, suitable for drawing operations. The dimensions of the heights of the prismatic and sliding guides are to offer maximum rigidity facing the high demands, limiting the deformation of the work surfaces to minimum values.

OVERLOAD AND COMPENSATION:

An overload protection unit is installed to protect machine components and installed tools. A safety valve discharges the oil from the chamber when for any reason the reached set value is higher than the nominal load.

For an effective balance of the slide and the dies, the compensation is by means of two pneumatic cylinders.

ELECTRICAL INSTALLATION AND SAFETY:

The control panel features a switch enabling the user to select the desired type of work in manual, semi-automatic or automatic position. Electrical and hydraulic manoeuvres are redundant and self-controlled. They incorporate an additional PLC for manoeuvre and safety.

Operation is carried out by low voltage two-hand push button and electric pedal.

Safety is guaranteed using lateral opening protections with level IV safety light curtains placed on the sides of the work area.

It meets and satisfies all the essential health and safety requirements in accordance with the CE standard.

| 100 Tons | 160 Tons | 200 Tons | 250 Tons | 300 Tons | 400 Tons | |

|---|---|---|---|---|---|---|

| H1 (mm) | 4200 | 4350 | 4700 | 4750 | 5000 | 5200 |

| H2 (mm) | 900 | 950 | 1000 | 1000 | 1000 | 1100 |

| W1 (mm) | 2250 | 2450 | 2550 | 2700 | 2800 | 2850 |

| W2 (mm) | 1700 | 1800 | 2000 | 2000 | 2100 | 2100 |

| D1 (mm) | 1950 | 2000 | 2100 | 2150 | 2150 | 2200 |

| D2 (mm) | 1950 | 2050 | 2050 | 2150 | 2150 | 2150 |

| 100 Tons | 160 Tons | 200 Tons | 250 Tons | 300 Tons | 400 Tons | |

|---|---|---|---|---|---|---|

| Press Capacity (ton) | 100 | 160 | 200 | 250 | 300 | 400 |

| Stroke per Minute (spm) | 60 | 50 | 40 | 40 | 40 | 30 |

| Nominal Tonnage Height (mm) | 5.5 | 6 | 6.5 | 7 | 7.5 | 7.5 |

| Stroke Adjustment (mm) | 150 | 150 | 150 | 150 | 200 | 200 |

| Max. Closed Mould Height (mm) | 350 | 400 | 450 | 500 | 500 | 500 |

| Table – Ram Distance (mm) | 500 | 550 | 600 | 650 | 700 | 700 |

| Ram Adjustment (mm) | 0-80 | 0-100 | 0-120 | 0-120 | 0-120 | 0-140 |

| Table Dimension (mm) | 900 x 1000 | 1000 x 1000 | 1000 x 1200 | 1100 x 1200 | 1100 x 1300 | 1100 x 1300 |

| Ram Dimension (mm) | 900 x 1000 | 1000 x 1000 | 1000 x 1200 | 1100 x 1200 | 1100 x 1300 | 1100 x 1300 |

| Motor Power (kW) | 11 | 15 | 18.5 | 18.5 | 22 | 30 |

Versatile PMV Series Mechanical Presses with variable stroke capabilities. Ideal for automotive, aerospace, and metal forming industries, featuring robust construction and advanced safety features.