Workshop C-Frame Combo Profi Press • 60 Ton • Motorised • 2 Speeds

Product Code: PPCMT60The 60 Ton C-frame Press Machine is a high-quality hydraulic press that is made in Europe with high-quality steel construction. It has a capacity of 60 tons and is designed for general assembly, straightening, and testing work pieces. The C-frame design makes it easy to work with different material sizes, and the movable worktable provides versatility. The press is also equipped with a manometer, pressure regulator, 2-speed switch, joystick, and adjustable worktable.

The key features of the press include a High-quality steel construction making it durable and long-lasting. A Capacity of 60 tons which means it can handle a wide range of materials. A C-frame design making it easy to work with different material profiles and sizes. A Movable Worktable providing versatility and allows you to work with different projects. A Manometer allows you to easily monitor the pressure of the press. A Pressure regulator enabling you to adjust the pressure of the press. A 2-speed switch allows the press operator to choose between two speeds for the press. An easy access Joystick making the press control easy and safe.

Please contact for prices

- Description

- Additional Info

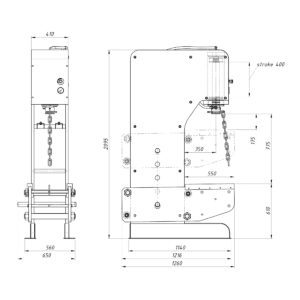

- Pressure force [tn]: 60

- Motor power [kW]: 2.2

- Working speed [mm/sec]: 3

- Approach speed [mm/sec]: 9

- Return speed [mm/sec]: 11.6

- Piston stroke [mm]: 400

- Vertical Daylight [mm]: 775

- Throat depth [mm]: 350

- Total length [mm]: 1300

- Total width [mm]: 650

- Total height [mm]: 2100

- Weight [kg]: 1250

- Integrated pressure manometer

- Pressure regulation

- Hydraulic unit with a 2-speeds handle

- In height adjustable working table

- Remote Hand Control

- 2-year warranty

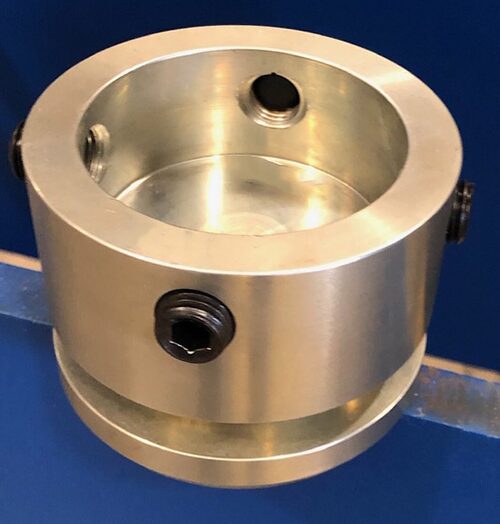

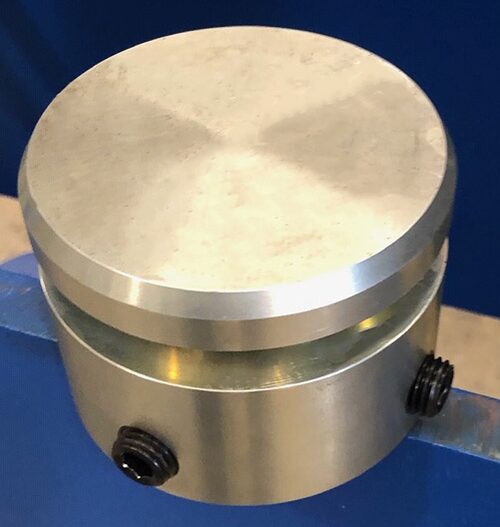

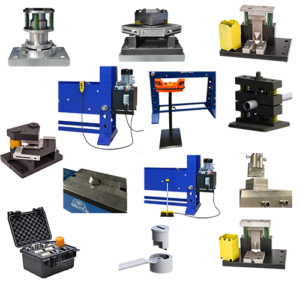

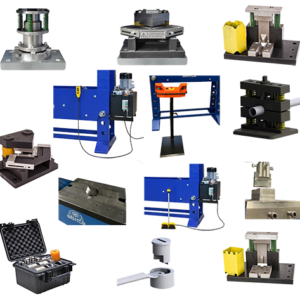

Optional Accessories & Tools

- V-Block sets

- Mandrel set

- Pressure pins

- Digital stroke read-out

- Foot pedal

- Table plate

What is a Workshop Press

A Hydraulic Workshop Press is a pressing machine that implements hydraulics to compress materials in a variety of applications. Like most shop equipment, hydraulic presses range in quality from basic models but WorkshopPress.co.uk only offers top quality RHTC hydraulic workshop presses. When purchasing an RHTC Hydraulic Press from us it will contribute to your company’s profitability. In addition, when a workshop, maintenance, manufacturing, or assembly area implements hydraulic workshop press machinery your capabilities are tremendously expanded and you then have the ability to perform a wide variety of different pressing processes and forming processes as well as folding, straightening, forming, riveting, and pressing work. RHTC presses offer usefulness, durability, reliability, functionality, and stability enabling the ability to get more use out of it, and more things are done efficiently saving you time and most importantly money.

Workshop Press Uses

Some Typical Shop Press Uses include: metalwork bending and folding, holding welding projects steady, punching, straightening uneven metal parts, bearing pressing, flattening warped parts, separating rusted parts, compressing, crushing used oil filters to remove excess oil, automobile part construction, jewelry-making, ammunition, and bracket bending.