T-Nuts and T-Slots: The Standards That Dictate Compatibility

T-nuts are an essential component in precision engineering, machining, and industrial clamping systems. However, not all T-nuts are the same; they must correspond precisely to the T-slots they fit into. This is where standards play a critical role in ensuring compatibility, strength, and efficiency in industrial applications.

The Two Key Standards: DIN 508 and DIN 650

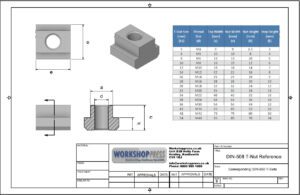

DIN 508 – T-Nuts Standard

DIN 508 specifies the dimensions, materials, and design of T-nuts, which are threaded fastening components designed to slide into T-slots. The standard defines key parameters such as:

- Thread size (M) – Metric thread sizes from M4 to M48.

- T-nut height (h) – Overall height of the nut.

- Top width (a) – The upper section width that sits inside the T-slot.

- Step height (k) – The depth of the lower part fitting into the slot.

- Length (e) – Overall length of the T-nut for proper engagement.

DIN 650 – T-Slots Standard

DIN 650 defines the dimensions of T-slots, which are machined into tables, fixtures, and mounting surfaces to accommodate T-nuts. This standard ensures consistency in:

- Slot width (b1) – The critical dimension determining nut compatibility.

- Slot depth – Dictating how deep a T-nut sits within the slot.

- Slot profile – Ensuring uniformity across machinery for standardized fixturing.

How Do These Two Standards Relate?

The DIN 508 T-nut standard is directly dependent on DIN 650 T-slot dimensions. Each T-nut size is designed to fit a corresponding T-slot, ensuring secure fastening and proper alignment.

Uses of T-Nuts

T-nuts are widely used in:

- Machine tool tables – Providing flexible and robust work-holding solutions.

- Assembly jigs and fixtures – Allowing modular and adjustable setups.

- Extrusion frame systems – Used in aluminum profile structures for automation and robotics.

- Vehicle engineering – Securely mounting components to standardized T-slot rails.

- Industrial workbenches – Creating adaptable and reconfigurable setups.

Industries That Rely on T-Nuts

Many industries depend on T-nuts for precision and repeatability, including:

- Metal fabrication – For securing workpieces in pressing, milling, and welding applications.

- Aerospace – Used in fixturing systems for high-precision components.

- Automotive – Essential in robotic welding stations and assembly lines.

- Manufacturing automation – As part of linear motion systems and adjustable mounts.

- Heavy machinery – Integrated into workstations and production equipment.

Why Standardized T-Nuts and T-Slots Matter

Using non-standard T-nuts or T-slots can result in:

- Incompatibility issues, leading to misalignment and improper fastening.

- Reduced strength, affecting safety and performance under load.

- Wear and damage, potentially leading to costly repairs or replacements.

- Difficulty in sourcing replacements, as non-standard parts are harder to find.

T-Slots in The Workshop Press Company UK Machinery

All machinery from The Workshop Press Company UK is manufactured with standardized T-slots according to DIN 650. This guarantees:

- Seamless compatibility with industry-standard T-nuts, clamps, and fixtures.

- Reliability and strength, ensuring secure work-holding in all applications.

- Ease of replacement, allowing users to source compatible parts without custom machining.

By using standardized T-slots, The Workshop Press Company UK ensures that its machines integrate seamlessly with a wide range of industrial tooling, maximizing flexibility and usability for customers.